On this page:

AUTONOMOUS MOBILE ROBOTS

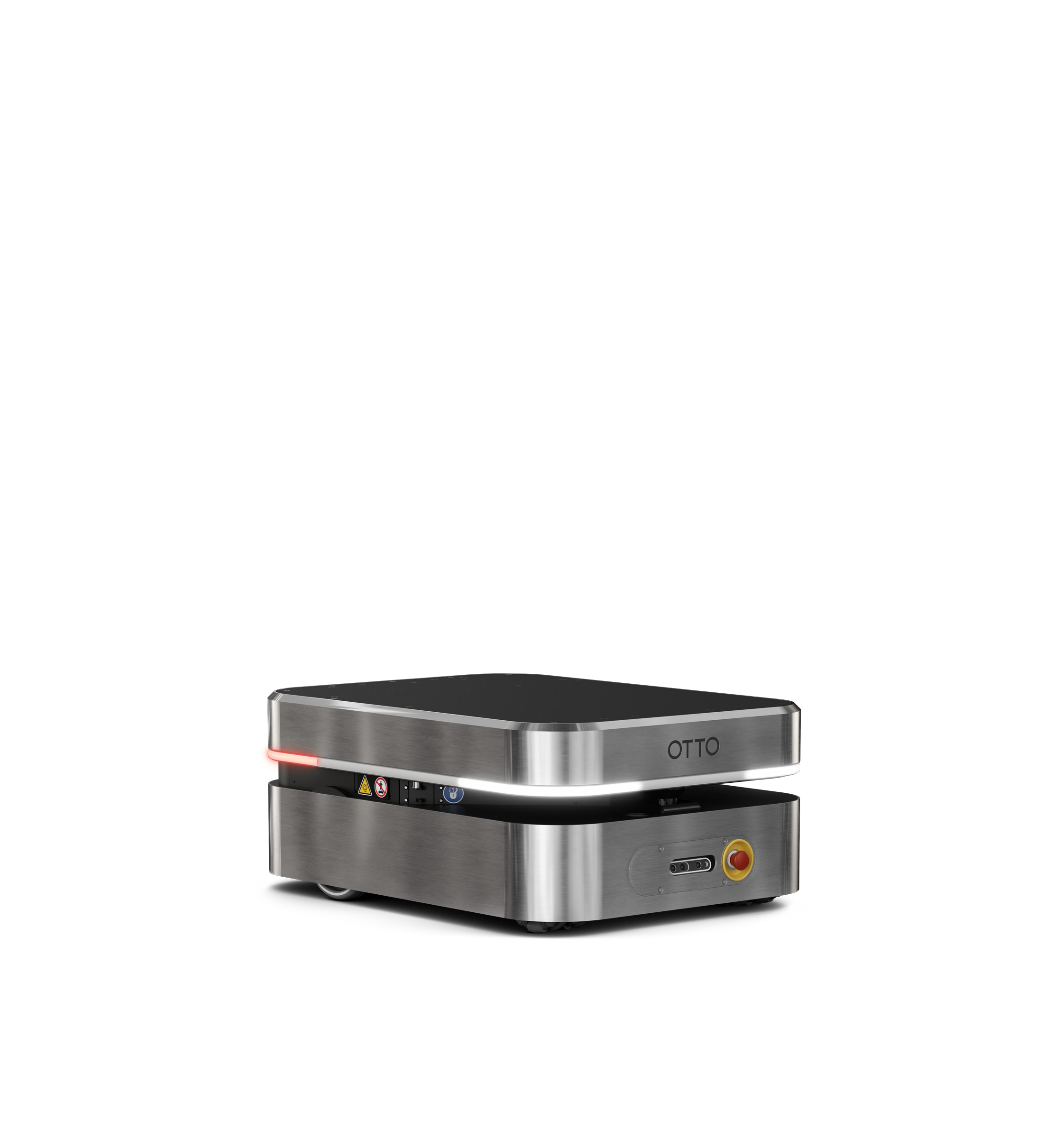

Meet OTTO 600

A tough and nimble AMR, designed to help you move mid-sized payloads quickly in tight spaces.

KEY SPECIFICATIONS

Payload capacity

0 kg

Maximum travel speed

0 m/s

Total footprint

0 x 0 x 0 mm

Charge time (10% to 90%)

0 minutes

Standards compliance

CE Marked, ANSI / RIA R15.08-1, ISO 12100/13849-1, FCC Part 15 Subpart B / ICES-003, ICES-002, EN 1175-1/60204-1

WHY OTTO 600

Move more in tight spaces

Unmatched Throughput

With the narrowest footprint in its class, OTTO 600 seamlessly moves materials in high-traffic, tight spaces at industry-leading average speeds.

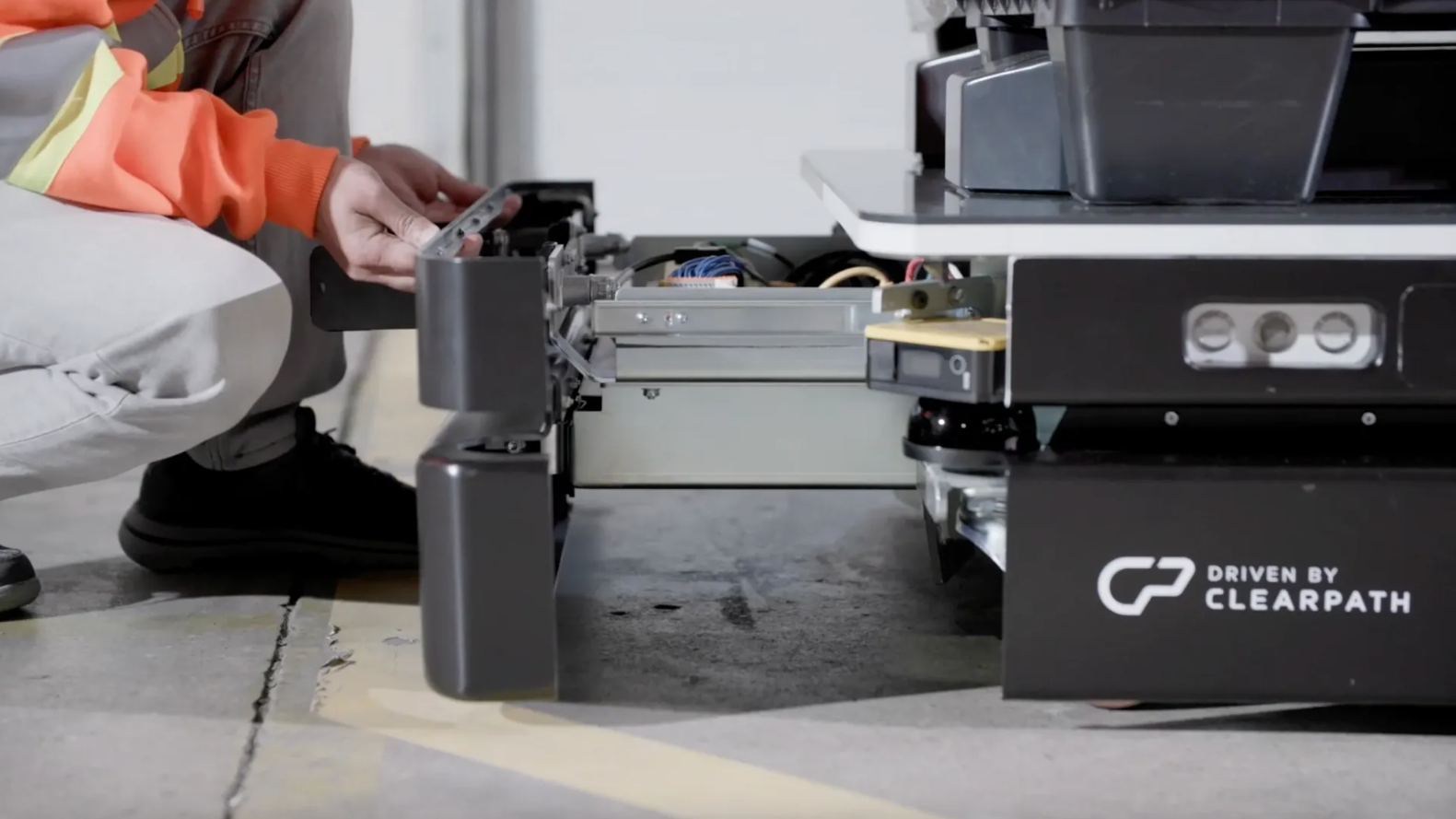

Simplified Maintenance

Should you need to, servicing your OTTO 600 is simple with rapid-access drawers that enable quick maintenance that can be tackled by a single person.

Improved Floor Space Utilization

With a narrow footprint and the same charging interface as the OTTO 1200, you can minimize the aisle widths and charging infrastructure required in your facility.

ATTACHMENTS

Unlock countless workflows with attachments

Autonomously move your mid-sized payloads with attachments designed for your narrow environments.

Lift

Move large totes and pallets to and from stands with the Nord Lift 80.

Cart

Functioning as a portable P&D stand, move large totes and pallets through flexible workflows with the Nord Cart.

Cart With Handle

Equipped with a handle, move large bins, boxes and totes through person-to-person workflows with the Nord Cart.

Don't see the attachment you're looking for?

Talk to a material handling expert about custom attachments, crafted just for your payloads.

OTTO Fleet Manager

Maximize the potential of your OTTO 600

The key to achieving peak efficiency with your OTTO AMRs is in the software. OTTO Fleet Manager empowers your fleet and existing systems to work in harmony through one connected, easy-to-use platform.

Behind the Chassis

Designed for the most dynamic environments

3D CAMERAS

Two forward-facing cameras support autonomous navigation and assist in detecting overhanging obstacles

DIFFERENTIAL DRIVE WHEELS

Provides agility and speed in crowded and dynamic factory environments

EMERGENCY STOP BUTTONS

Manually stop the robot with two buttons placed on each side

LiDARs

360° field of view with two corner LiDars to detect surrounding objects and estimates distance for safe and efficient operations