Blog

7 million hours and counting: How the most experienced AMR solution elevates facilities worldwide

After fifteen years of innovation, OTTO by Rockwell Automation’s autonomous mobile robot (AMR) solution has achieved over 7 million production hours—the collective number of hours OTTO AMRs have driven in production environments around the world. Since its founding, OTTO’s award-winning software has become an expert in productively managing over 100 AMRs in a single fleet, delivering over 700,000 payloads monthly.

With over seven million hours moving payloads around mission-critical, dynamic manufacturing facilities, OTTO has become the most experienced material handler in the industry. Equivalent to 3,400 years of work experience, OTTO dedicates its growing expertise to improving safety, increasing efficiency, and empowering employees in hundreds of facilities around the world.

Elevating manufacturing facilities worldwide

Since the first OTTO AMR—an OTTO 1500—began driving in manufacturing facilities, the software has been continuously learning, becoming smarter with each hour of production experience.

Over the last 7 million hours, OTTO’s software has absorbed all of these learnings and transferred that knowledge to every deployment past and present, elevating material handling for manufacturers worldwide. OTTO gathers these insights from production environments to improve the software, pushing these improvements out in semi-annual software updates.

With every software update we get, it just keeps getting better and better.

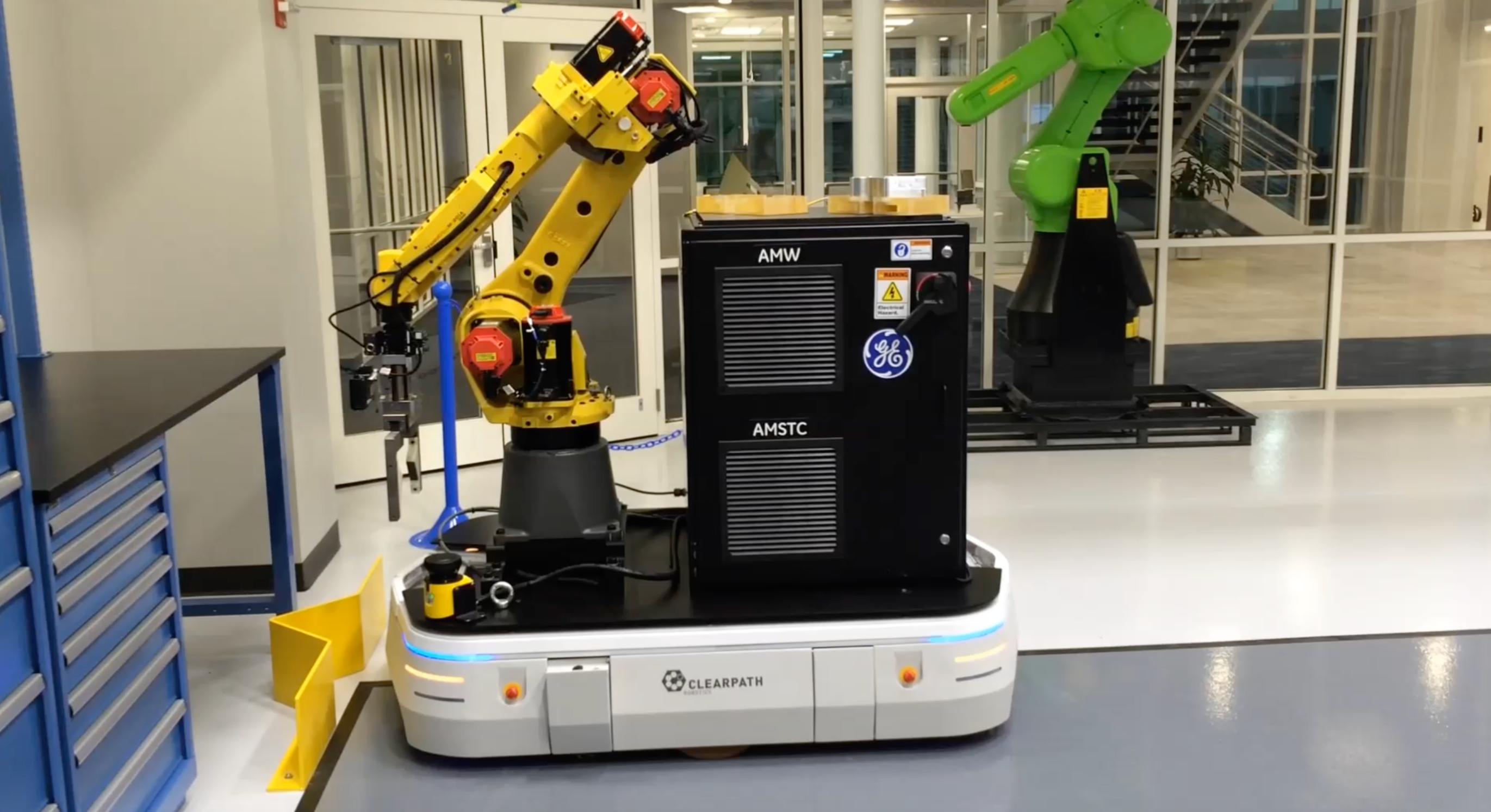

Joe Germait, Manufacturing Technician at GE Healthcare

Some of OTTO’s first AMRs deployed at a manufacturing facility are still operating today. GE Healthcare, and many of our other long-standing and newer customers, are providing the production environment for OTTO to gain hours of experience, which over the years has delivered many benefits for manufacturers, including:

- A 6x throughput increase at a CPG manufacturing facility moving plastic rigid containers

- 40% smaller repair cells leading to a 66% increase in productive floor space at a manufacturing facility moving medical equipment

- An estimated $1.3 million saved within one year of implementation at an aerospace facility

- A 15% reduction in workcell sizes and an 11-month ROI at an automotive facility moving components in stacked totes

- A 97% reduction in cycle times, from 15 minutes to just 30 seconds at an industrial facility moving stacks of paper

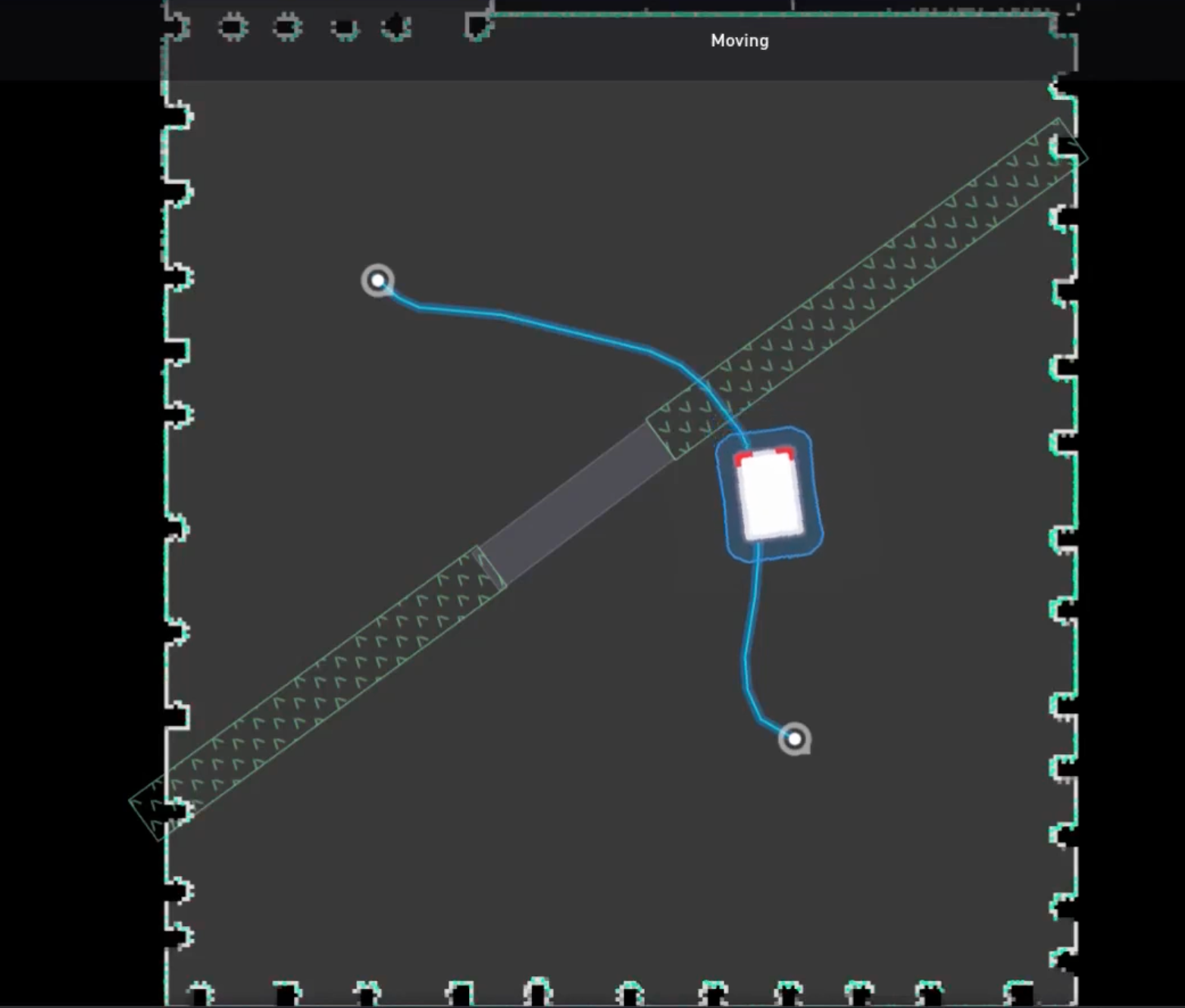

Image 1: One of the original OTTO 1500 AMRs at a GE Aerospace facility. At the time, the robot’s colorway was white.

When our customers are dedicated to continuous improvement in their facilities, OTTO is able to continuously improve our software as well. This not only elevates material handling at our customer facilities, but in the industry as a whole. Manufacturing has been transformed by AMRs and together with our customers, we will continue to shape the industry and grow alongside it.

AMR software has elevated manufacturing facilities to achieve next-level efficiency. To learn more about the features behind the industry’s most experienced AMR software, watch the webinar, “The essential role of software for successful AMR deployments.”

Subscribe to our newsletter

Stay in the loop on product news, case studies, upcoming events and more.