Blog

AMA: What should I look for when assessing AMR demos at trade shows?

In this blog series, manufacturing facilities and warehouses ask their top industry and product questions, and OTTO’s material flow experts answer them.

Once you have determined that autonomous mobile robots (AMRs) are the right solution for your facility, the next step is to evaluate various AMR providers and identify which vendor best meets your needs. The most efficient way to assess multiple AMR solutions at once is by attending industry trade shows. There, manufacturers can speak directly with automation specialists and watch the robots in action.

Each AMR provider will demonstrate their fleet differently at trade shows, which can be revealing of their capabilities. Since trade shows are the best opportunity for vendors to demonstrate their fleet to thousands of potential customers, they will put their best foot forward. Thus, when walking the show floor to evaluate AMR solutions, look for these six signs of confidence in robot demos:

- Is their fleet management software shown or hidden?

- Are the AMRs driving on concrete, or did they install flooring on top?

- Are the AMRs stationary or moving?

- Are there multiple robots sharing the same space, or are they isolated?

- Is an employee glued to their laptop watching the demo?

- How safe is the AMR demo?

1. Is their fleet management software shown or hidden?

A fleet of AMRs is only as powerful as the software that supervises it. As your fleet scales, sophisticated fleet management software becomes increasingly important to maintain productivity by proactively avoiding blockages and assigning jobs to the right robot at the right time.

A vendor that is proud of their software should be excited to show it off in their booth. It should be displayed on large screens, and manufacturers should be able to click around independently to experience just how easy it is to use.

Video 1: OTTO’s booth at MODEX 2024, where employees are demonstrating software capabilities on large screens.

2. Are the AMRs driving on concrete, or did they install flooring on top?

AMRs need to move across your facility’s floors smoothly, without stopping, losing the payload or disrupting productivity. Manufacturing floors, however, are not smooth, and instead are riddled with cracks, bumps, and uneven sections.

Vendors that trust the robustness of their AMRs will drive on the concrete that is inherent in the exhibition hall, mimicking an imperfect factory floor, rather than installing smoother flooring on top of the concrete.

3. Are the AMRs stationary or moving?

From initial set up to managing day-to-day work to maintenance and optimization, your chosen AMR solution should be easy to use without constant assistance from your vendor.

Vendors have less than one week of set-up time at trade shows, which means if their AMRs are moving rather than stationary in the demo space, the solution is likely easy to set up and debug.

Video 2: In this sped up video, a non-engineer shows how easy it is to use OTTO Fleet Manager. In just six minutes, the user maps a space, creates traffic rules, sets up a charger, sets cart pick-up and drop-off locations, creates a job to move the cart and then autocharge, and runs the job.

4. Are there multiple robots sharing the same space, or are they isolated?

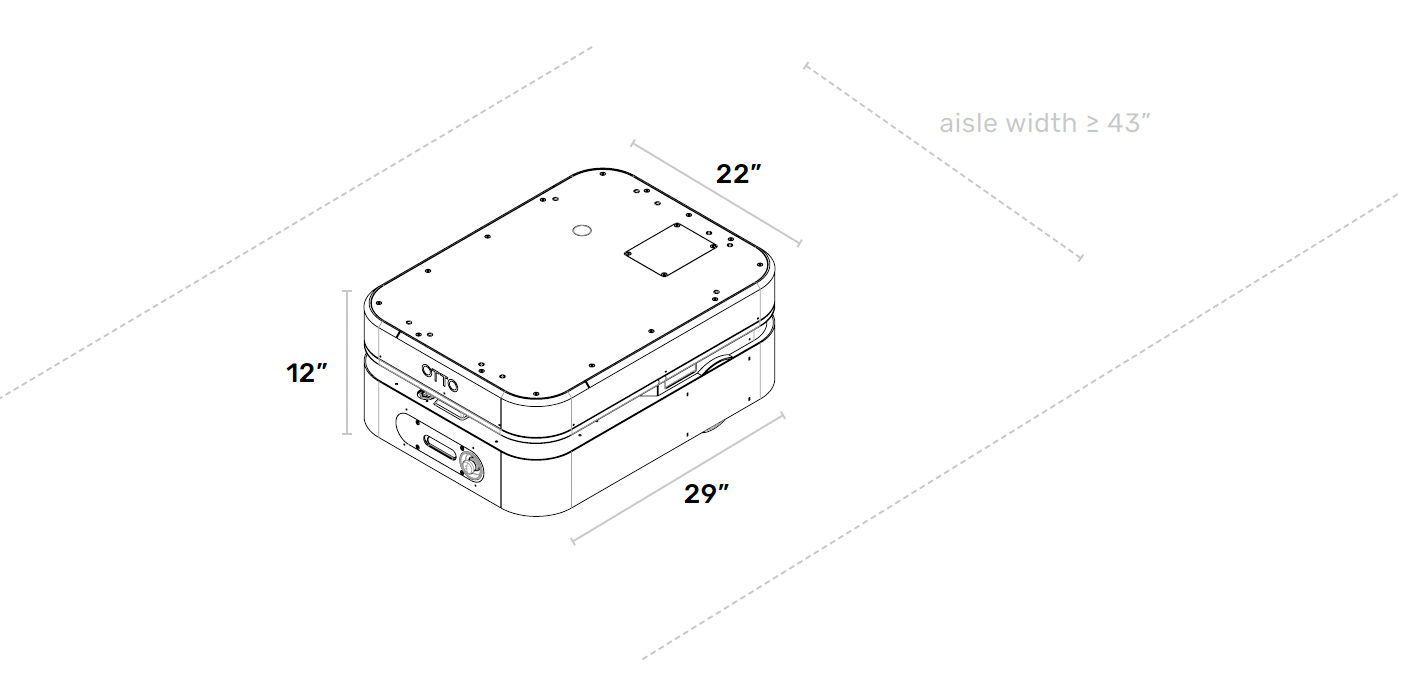

As your AMR deployment scales from a few robots to dozens, you need to ensure the solution you chose can scale with you. In your facility, AMRs will need to share the same space, work with the same infrastructure, and navigate the same narrow aisles.

When assessing an AMR demo, consider if there are multiple robots sharing the same space, or if they are isolated in separate loops. If they’re sharing the same space, the vendor is likely confident in their traffic congestion capabilities and their robots will continue to be highly productive even in tight spaces.

You can also check if the robots in the same space are sharing a workflow, with multiple AMR types using the same pickup and dropoff stands or conveyors, for example. This means the solutions can integrate together in your workflows to efficiently move more material across your facility.

5. Is an employee glued to their laptop watching the demo?

In a facility, manufacturers cannot dedicate a team member to watch the fleet management software all day to ensure the robots are doing their jobs. They need to trust that the solution they select will be reliable in their mission-critical operation. At a trade show, if you can spot an employee glued to their laptop, watching the demo to ensure it runs smoothly, this likely indicates a lack of confidence in their system’s reliability, which could transfer to your facility upon deployment.

6. How safe is the AMR demo?

The AMRs you implement will need to work alongside your existing equipment and most importantly, your people. This means the vendor you select needs to be confident in their safety above anything. If a vendor has an insurmountable barrier around the demo, that may indicate a lack of confidence in the safety of their robots.

The vendors that are most confident in their robots will demonstrate their safety features proudly. For example, employees may step in front of the robots abruptly in front of large crowds, and may even bring guests into the demo space to test the safety features for themselves.

Video 3: OTTO’s booth at MODEX 2024, where employees are bringing attendees past the minimalist barrier into the demo space to experience the safety features first hand.

By using these six tips to assess demos at trade shows, you’ll build a stronger understanding of which AMRs best meet your needs.

To help guide you through this process as you walk the show floor, download the interactive worksheet and bring it with you to Automate.

Download the worksheet

Subscribe to our newsletter

Stay in the loop on product news, case studies, upcoming events and more.