Blog

3 supply chain trends from the 2024 MHI Industry Report and MODEX, their leading material handling trade show

Material Handling Institute (MHI) hosted its largest material handling trade show in North America this week—MODEX. The 2024 show saw over 45,000 manufacturing and supply chain professionals engaging with over 1,000 exhibitors and 165 educational sessions.

Image 1: OTTO Lifter on the MODEX 2024 show floor.

During the event, the show organizer, MHI, launched their 11th annual MHI Industry Report, which studies technologies and innovations that are transforming supply chains worldwide. With 1,675 respondents, this year’s report focuses on making a collaborative supply chain that is tech-driven and human-centric.

The focus on technology in supply chains is undeniable. But supply chains are run by people, and human-centricity is the key.

John Paxton

CEO of MHI (2024 Industry Report, page 4)

Here are our top three takeaways:

- The global talent shortage and increasingly complex customer demands are causing manufacturers to evaluate innovative solutions

- Manufacturers are ready to invest in innovative technologies, including robotics and automation, to create a competitive advantage and disrupt the industry

- Manufacturers are investing in technologies that improve workers’ lives through collaboration, not to replace them

1. The global talent shortage and increasingly complex customer demands are causing manufacturers to evaluate innovative solutions

In the past nine MHI Industry Reports, the “talent shortage” and “hiring and retaining qualified workers” have been top five industry challenges, and 2024 is no exception. This is a trend we have witnessed for a long time, and one that is not going away any time soon.

This will remain a future trend as we look to the next 5 years.

John Paxton

CEO of MHI during their MODEX keynote session

With 2.4 million manufacturing jobs expected to go unfilled by 2028, it’s no wonder the global labor shortage is this year’s second most impactful challenge. As the report says, “the skill sets required to operate and manage emerging technologies place supply chain organizations in direct competition for talent with tech giants like Apple and Google.”

Image 2: 2024’s top industry challenges, including the talent shortage and customer demands.

Coming in third on the list of top challenges is customer demands on response times, shipments, customization and pricing. Globalization and improved access to worldwide travel has led to growing and more complex consumer expectations, resulting in manufacturers innovating with flexible solutions to keep up with this demand.

These two top challenges are consistent with what we heard from MODEX attendees looking at autonomous mobile robots (AMRs) as a solution to increase efficiency and combat the global labor shortage.

2. Manufacturers are ready to invest in innovative technologies, including robotics and automation, to create a competitive advantage and disrupt the industry

To solve these top challenges, manufacturers are turning to innovative solutions, such as robotics and automation. While 29% of manufacturers use some kind of robotics and automation technology today, another 54% plan to adopt it in the next five years—an increase from 2023’s report.

Most manufacturers (55%) are increasing their investments in supply chain technology, including robotics and automation, with 88% planning to invest more than $1 million and 42% planning to invest more than $10 million.

The significant rise in investment since [2019] suggests that businesses are not just reacting to short-term challenges, but instead are strategically positioning themselves for long-term success. They are leveraging digital technologies to make their supply chains more responsive and resilient, helping them adapt to changing market conditions, anticipate disruptions, and seize new opportunities.

2024 MHI Industry Report, page 10

This is representative of what we saw and heard on the MODEX show floor. From stretch wrappers to barcode scanners to shelving and storage solutions, supply chain technologies spanning the industry were on display.

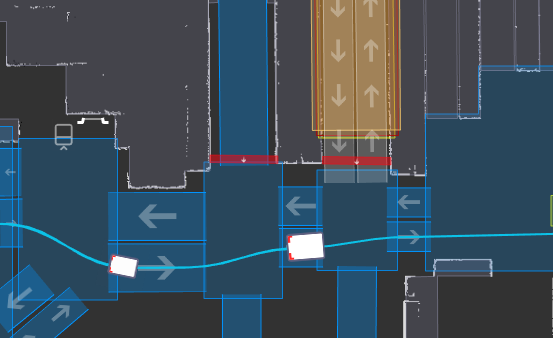

Image 3: Human-size robots moving bins at MODEX 2024.

Attendees came to the OTTO booth knowledgeable about the AMR solution and ready to invest in a technology that will solve their key challenges. OTTO demonstrated three key workflows commonly seen in customer facilities:

- Cart picking with two OTTO 100s, triggered via tablets and industrial buttons

- Finished goods transfer from a conveyor with OTTO 1500 featuring a conveyor attachment

- Finished goods transfer between a P&D stand and a floor location with OTTO Lifter and OTTO 1500 featuring a lift attachment

These robots worked collaboratively to demonstrate potential manufacturing workflows and maximize productivity in space-constrained environments, seen in the video below.

Of all supply chain technologies listed, robotics and automation has the highest potential to disrupt the industry and create a competitive advantage, with a combined 52% of respondents excited about the technology’s possibilities.

Image 4: 2024’s impact of technologies, with robotics and automation leading the list of those that have the potential to disrupt the industry or create competitive advantage.

3. Manufacturers are investing in technologies that improve workers’ lives through collaboration, not to replace them

As manufacturers increasingly invest in innovative supply chain technologies to solve their top challenges, they are looking to design a solution that works with their employees.

Solutions with a bilateral exchange that pairs humans and technology together have the best use cases; they allow the workforce to become more flexible and less task-oriented.

Dr. Randy Bradley

Associate Professor of Supply Chain and Information Systems Management at The University of Tennessee (MHI Industry Report, page 24)

The report uncovers six main reasons manufacturers are merging technology with human-managed activities, including empowering workers to be more productive, increasing safety, improving long-term resiliency and efficiency.

Image 5: Manufacturers provided their top reasons for merging supply chain technology with human-managed activities in the 2024 MHI Industry Report.

At MODEX, conversations with manufacturers proved the report’s conclusions were accurate. Manufacturers are not looking for AMRs to replace humans, but instead to work alongside them to help elevate their roles and their skill sets.

Today’s workforce is thinking about how and why we should be doing things differently.

Dr. Randy Bradley

Associate Professor of Supply Chain and Information Systems Management at The University of Tennessee (MODEX keynote session)

Educational sessions focused on the collaborative “jobs of tomorrow” as well, with an entire track dedicated to “workforce and labor” and sessions such as “how to boost warehouse worker productivity and increase satisfaction.”

Automation is increasing overall worker satisfaction by making jobs better and more tech-forward.

2024 MHI Industry Report, page 38

The 2024 MHI Industry Report and our experience at MODEX provided a lot of insight into the challenges and mindsets of manufacturers. Supply chain leaders are now ready to invest in solutions that solve their labor shortage and high customer demand challenges, while working collaboratively with their people.

We look forward to exhibiting at LogiMAT in Stuttgart, Germany from March 19–21 and Automate in Chicago, USA from May 6–9.