Blog

How a $13B Fortune 500 CPG manufacturer navigated the 5 stages of AMR selection

In 2017, one of the world’s largest packaging manufacturers began evaluating autonomous mobile robots (AMRs) at their Bowling Green, Kentucky facility. Ultimately deploying 17 OTTO 100 AMRs and two OTTO 1500 AMRs, they achieved two million annual deliveries and $250,000 in monthly savings before scaling to four additional facilities in the United States.

Driven by customer demands to continually adapt product lines, the manufacturer sought an automation solution that could scale with production needs while preserving productivity. This is how the $13B packaging leader navigated the five stages of the autonomous mobile robot (AMR) selection process to evaluate, validate, and select a solution with confidence.

Choosing the right automation solution

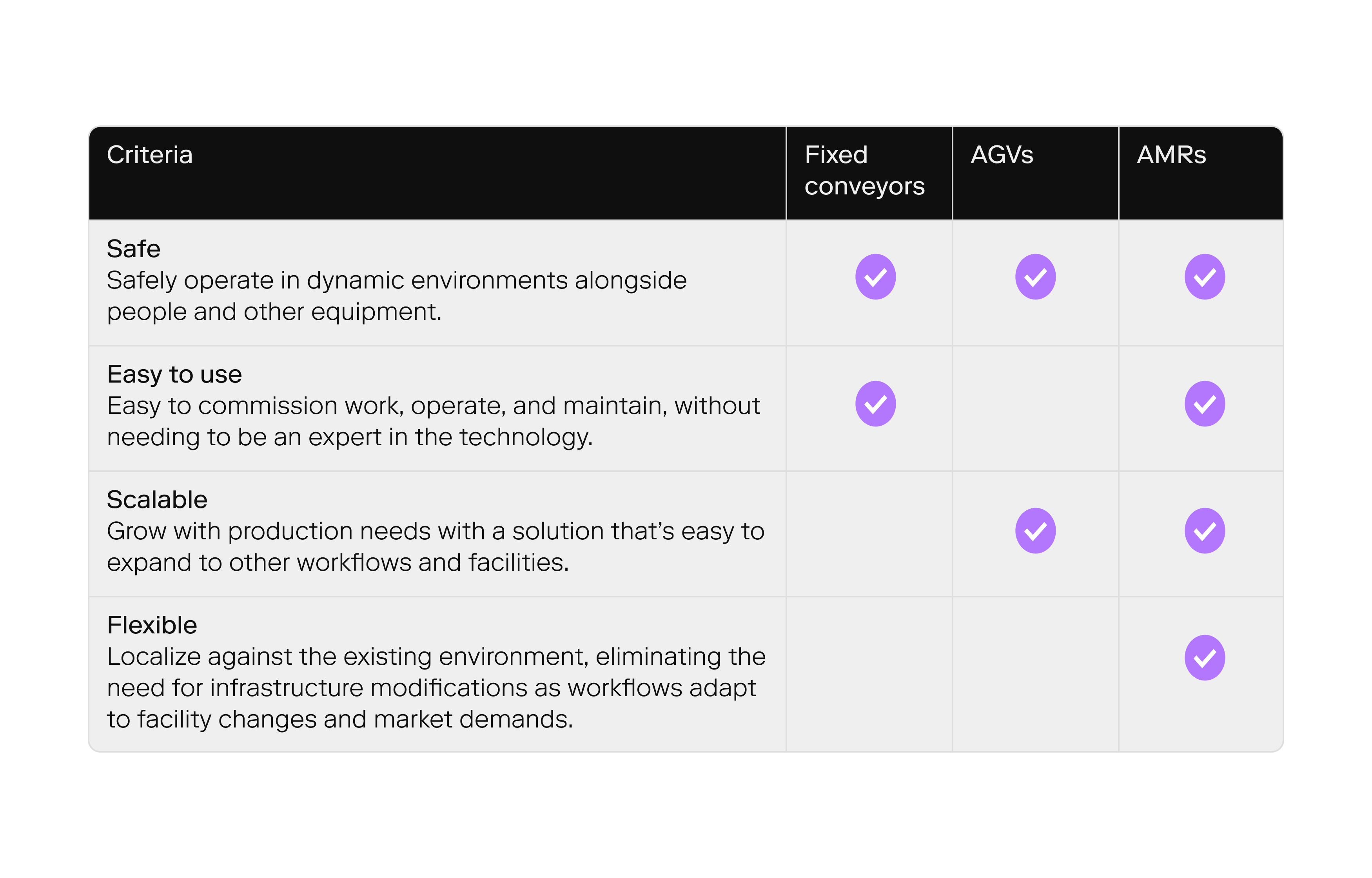

To automate finished goods takeaway and pallet transport from the palletizer to the shrink-wrapper, the Director of Automation evaluated three solutions based on safety, ease of use, scalability, and flexibility: fixed conveyors, automated guided vehicles (AGVs), and AMRs.

Image 1: The manufacturer’s criteria when evaluating fixed conveyor systems, AGVs, and AMRs.

Ultimately, AMRs were identified as the best fit for their operational needs, and the Corporate Automation team conducted independent research—online, at trade shows, and via an RFI—to identify the vendors best equipped to meet the facility’s requirements.

Evaluating for the best-fit AMR solution

During independent research and in 1:1 conversations with shortlisted vendors, the Director of Automation and his team assessed how well each solution met their specific needs. Some of their top technical and long-term success considerations included:

- Does the vendor put safety first?

- How well do the robots withstand and adapt to industrial environments?

- How adaptable is the robot?

- How mature and well-supported is the solution?

- Is the vendor a solutions-oriented company, dedicated to solving operational challenges?

- Is the software advanced and intelligent enough to support dynamic operations?

To dive deeper into this CPG manufacturers’ five stage journey to AMR selection—including how the Director of Automation aligned key stakeholders—download the full case study.

Subscribe to our newsletter

Stay in the loop on product news, case studies, upcoming events and more.