Blog

Industry 4.0 readiness: The connected factory is coming

In the midst of global change and innovation, there are indications that manufacturing has not kept up. It needs to. With Fortune 500 companies disappearing there is unprecedented threat, but also opportunity, in the world of manufacturing. It’s called Industry 4.0, and it's giving rise to a new type of facility: the connected factory.

Information and the connected factory

“The physical world is becoming a type of information system,” says Simon Drexler here at OTTO Motors. “The one who controls the material flow, controls the info. The one who controls the information has the power.” Do you have the power? You can.

“The connected factory of Industry 4.0 consists of interconnected industrial equipment that accesses and analyzes centralized operational data,” says Drexler. “We can look at companies like Fedex, who have stated that information is more valuable than the package.”

Industry 4.0: An industrial revolution

Industrial revolutions usually take about a decade, when looking back over a 15-year period, according to Drexler. “We can see that Industry 4.0 started in 2015. This means it will probably reach maturity around 2025.”

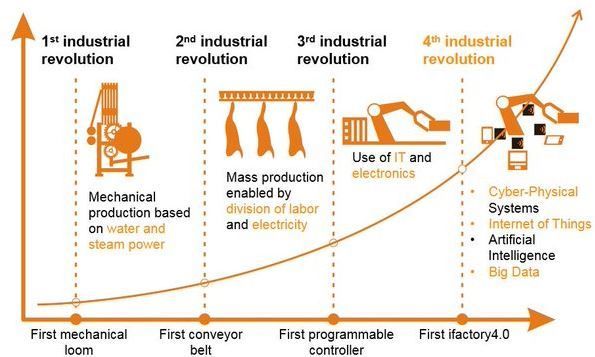

But what exactly is Industry 4.0? Industry 4.0 is essentially the move from humans working with computers, to computers working with humans: the essence of the optimistic view of benign AI. It represents the implementation of Big Data, AI and IoT: the Internet of Things.

Photo credit: @sciencepartner on Twitter

Believed to be a term first coined by the German government, Industry 4.0 follows:

Industry 1.0: defined by textiles, steam power and the manufacture of iron

Industry 2.0: characterized by steel, other raw materials and technology

Industry 3.0: powered by oil, fossil fuels and computers entering the workplace

Is your factory connected?

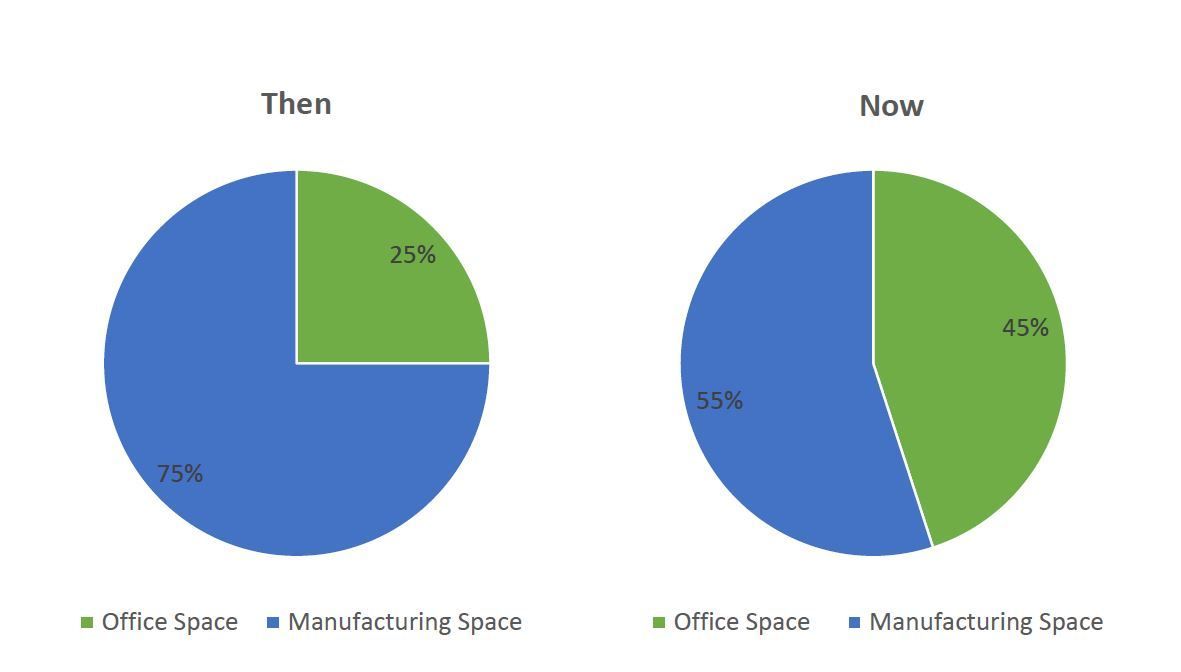

According to OTTO Motors' Drexler, the 4.0 exchange involves machine learning, autonomous systems and robotics, instead of low-intelligence computers operated by humans. Are your humans ready for computers to work with them? There are numerous signs that will indicate your workforce is ready for Industry 4.0. Perhaps no clearer sign of preparation, is the following progression of the average manufacturing concern:

The reason for this progression is that Industry 4.0 equipment takes less space and people can now be deployed in more complex tasks. (Note: these numbers are based on our hypothesis).

OTTO Motors offers an intelligent, interconnected solution, yielding user data like real-time material. Systems like these enable manufacturers to control their material and, ultimately, their most valuable resource: information.