Blog

The labor shortage is killing American manufacturing. Here’s how AI can bring it back to life.

Originally posted on Forbes on August 28th, 2022.

US manufacturing is poised for a significant resurgence. The supply chain debacles caused by the pandemic have shown the weakness of an over-dependence on a long supply chain, especially one outside the US.

Further, the rising tensions with China have caused the US to question its dependence on Chinese manufacturing for economic success. These issues have changed the commitment of US manufacturing firms to build locally.

The problem is—American manufacturing is critically short of the labor it needs to drive that revolution. There simply are not enough skilled workers to do the job, nor enough unskilled workers willing to learn.

Necessity truly is the mother of invention, however. The manufacturing labor shortage has paved the way for widespread deployment of some very exciting innovations in Artificial Intelligence for manufacturing. So potent are these developments that McKinskey predicts they will create some $3.7 trillion in value by 2025.

But before we get into it, let’s take a quick look at the labor crisis that is fomenting the revolution.

Here’s how bad the labor problem is in American manufacturing

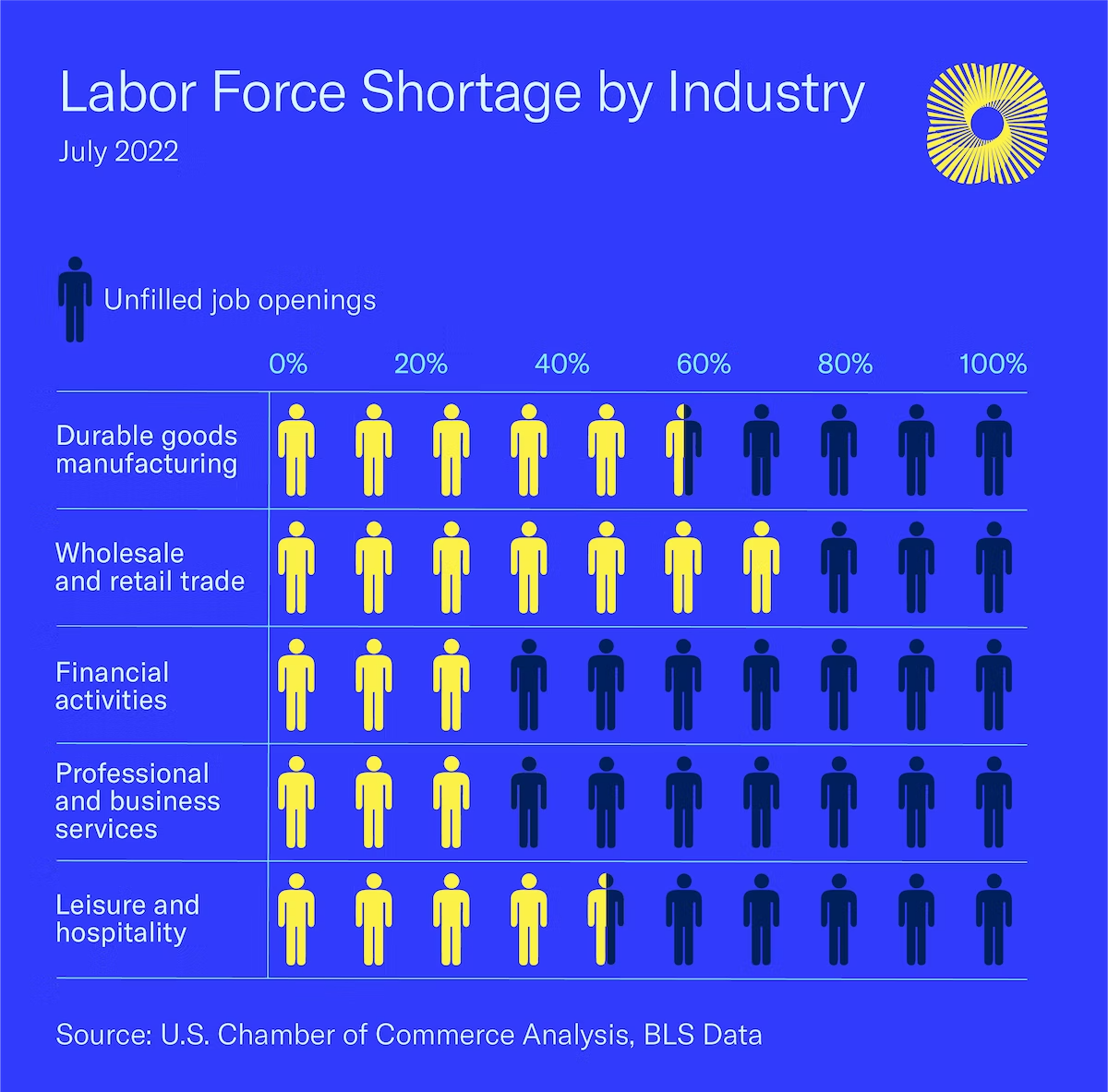

Even if every skilled worker in America was employed, there would still be 35% more unfilled job openings in the durable goods manufacturing sector than skilled workers capable of filling them. Deloitte predicts a shortage of more than two million American manufacturing workers by 2030, representing an opportunity cost of $1 trillion dollars per year.

Source: U.S. Chamber of Commerce Analysis, BLS Data

Left unchecked, things will probably get worse, not better. There are still some 40 million Baby Boomers in the workforce—about 25% of the total workforce, many of whom in “old school” manufacturing roles. As Boomers retire, younger workers are avoiding manufacturing jobs in favor of technology, healthcare, and other opportunities where working conditions and compensation are more attractive.

The United States could quickly ramp up immigration from countries where workers are eager to obtain American employment, but that comes with its own set of challenges, and would require more political sorcery than I can imagine possible. Besides, employers may be wary of training new skilled labor only to see their operations shuttered once again during the next lockdown.

In order to keep the machines turning, American manufacturers need to find alternatives to human labor.

AI can be a big part of the labor shortage solution

Part of the solution to this problem, unsurprisingly, is Artificial Intelligence. As with other industries, it is inevitable that many formerly human jobs will be replaced with AI. But instead of worrying about jobs at risk from AI, in this case you should be thinking about how AI can help keep your operations running and your human staff employed.

Here are just a few of the ways that AI in Manufacturing will help mitigate the labor shortage and revolutionize how products are made on US soil:

Robotic automation

Robots have been used for decades in fields like automotive manufacturing and steelworks, where they have performed repetitive production floor operations such as heavy lifting and joint welding. However these conventional robots were designed only to execute very narrowly-defined tasks under extremely predictable circumstances.

Today, artificial intelligence applications like Siemens’ Simatic neural processing unit are empowering robot arms to grasp and manipulate objects regardless of their orientation, speed, or placement. That means that robots and “co-bots” (robotic assistants designed to work alongside humans) can be trained to perform a wide variety of assembly line work, just as humans do. Meanwhile, Autonomous Guided Vehicles (AGVs), armed with AI functions like mapping, surface anomaly detection, and object avoidance technology, can transport parts and finished goods through warehouses and factory floors in place of loading crews and forklift operators.

OTTO Lifter, an autonomous forklift, turning a corner to deliver a pallet.

Together, these AI-powered robotic innovations can save at least 75% of the labor costs of using humans alone, enable 24 hour continuous production, and help avoid injury from assembly line dangers, heavy materials handling, and repetitive movements. It is no wonder that modern robotics is already driving a reversal of manufacturing fortunes in places like Singapore and South Korea. Why not do the same in the United States?

Additive manufacturing

Another area where AI is helping to alleviate the manufacturing labor shortage is in 3D printing. According to the conventional approach, highly-skilled designers and engineers must leverage years of experience and a “best guess” approach to arrive at the best design solution. But AI now empowers a rapid, generative approach to developing complex and highly optimized design solutions that can be produced quickly through 3D printing.

Machine learning in software systems like Autodesk’s Netfabb, for instance, allow manufacturers to input design parameters and request the most efficient, effective, and manufacturable options. Once a design is selected, AI from companies like NNAISENCE use neural networks and digital twins to predict, monitor, and eliminate defects in the additive manufacturing process, helping to avoid costly delays and mistakes. AI software like Intellegens’ Alchemite can even be used to imagine new and exotic materials suitable for specific manufacturing and product usage needs.

Were all of these incredibly complex functions to be performed by humans alone, they would require much larger teams of highly-skilled engineers and designers, and would often result in inferior results.

Machine vision

When you picture a manufacturing assembly line, you probably first envision a conveyor belt of products being whisked from one station to the next, whereupon human workers inspect products as they make their way along. In most manufacturing environments, that really isn’t far off from the truth. It is repetitive, labor intensive, and error-prone work, but it is vital to the quality assurance process.

Enter Autonomous Machine Vision (AMV), led by AI companies like Inspekto and Matroid. Using cameras and AI that recognizes the shape, orientation, and condition of assembly line products under various lighting conditions, AMV systems can count and track items, spot defects, and sort products accordingly, as they race by. This eliminates much of the need for human eyes and hands in the QA process.

Machine vision can also be used to support packing, palletization, and cargo loading, saving labor, time and money. Solutions from companies like RobitIQ and Spiroflow can determine the optimal palletizing method, for instance, whereupon a robotic arm grips and places cartons on pallets automatically.

OTTO is equipped with the latest laser and 3D camera sensors to operate in the most dynamic manufacturing environments.

Production optimization

When production machines go down, it often requires specialized analysis and repair agents, often dispatched from the maker, costing time and money. Not only can AI from providers like Vanti and 3DS be used to monitor machine and mold wear so that preventative maintenance can be scheduled for an optimal time, but it can also monitor temperature, humidity, and running variances for different products and materials, so that production machines can be optimized based on current conditions.

When something does go wrong, AI can analyze all of the possible reasons and propose the best probable course of action. That’s something that only a highly experienced human maintenance engineer can do in most factories.

But it isn’t just about maintenance and damage control. AI-powered cloud and edge systems like GE’s Brilliant Manufacturing Suite and Siemens’ Mindsphere are working to connect and manage the entire end-to-end manufacturing process from design to demand planning and material inventory, to energy consumption to endgame logistics.

The need for AI in manufacturing is even greater than you think

Imagine anthropomorphic robots with such a broad range of physical function and AI-powered adaptability that they will be able to do almost any manual labor that humans can currently do. When that happens, what difference will the cost of labor in developing countries make as a competitive advantage? AI-powered manufacturers won’t have to recruit and train nearly as many workers. They will worry less about the next pandemic and lockdown. They will avoid many of the single-source challenges that came along with our current supply chain management crisis. And much more.

As Artificial Intelligence systems are exposed to more and more data, they will continually improve, creating a flywheel effect that will put you right out of business if you miss the train. However, this revolution also has the unique power to wholly rejuvenate American manufacturing, perhaps even making it once again amongst the most competitive in the world.

The AI manufacturing revolution is happening right now, not at some unimaginable point on the horizon. This labor crisis is not a passing annoyance. It is part of the new business landscape that we should expect for years to come. Manufacturers who position AI as the key driver of their success will reap the benefits within our current decade.