Blog

7 key considerations when assessing AMR solutions

Material handling is one of the biggest consumers of labor in your operation. In an April 2023 webinar, it was not surprising that 75% of attendees were past the “challenge identification” stage of their automation journey. Innovative manufacturing facilities are automating the material handling process with autonomous mobile robots (AMRs) to save money, improve efficiency, keep people safe and ensure business continuity. Once you have determined that AMRs are the right solution for your facility, the next stage is identifying the types of AMRs best suited to automate your material handling workflows.

Here are seven factors to consider in your search for the right AMRs for your facility:

1. Payload

This is all about what you’re moving. Your payload requirements—such as dimensions, weight, and center of gravity—need to match the AMR solution that you select. It’s important to consider every possible scenario, including half full pallets and overhanging pallets. This will be the easiest way to begin filtering your list of vendors.

A lot of the time, AMR vendors classify their AMRs based on capacity. For example, OTTO Motors has the OTTO 100 for 100 kg... And a lot of the other vendors have a similar kind of set up as well.

Tom O’Neill

Senior Product Manager, OTTO Motors

Image 1: The OTTO AMR lineup includes small, medium and heavy class vehicles, both flatbed and forked.

2. Use Case

If payload is about what you’re moving, then use case is about where you’re moving it. There are three main use cases that material handling AMRs are typically used for:

Image 2: AMRs are capable of handling many different workflows to bring productivity improvements to your facility.

a) Bringing materials to and from people

b) Bringing materials to and from automation equipment

c) Moving materials to and from racks and near the floor

It’s important to determine what your specific use cases are so you can determine which vendor is able to support them.

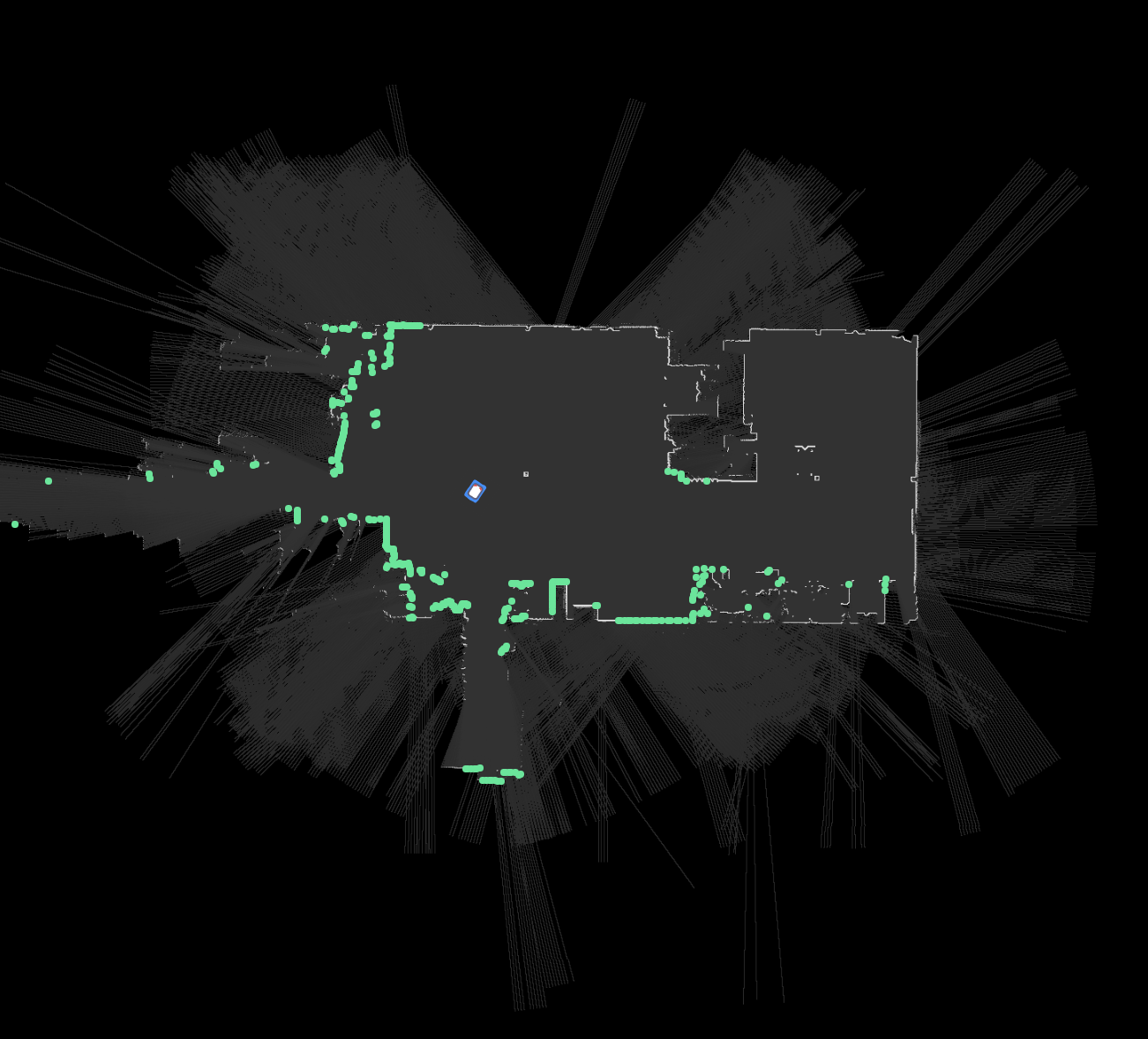

3. Facility

Automation isn’t a one-size-fits-all investment. Some facilities already have a high level of automation with fixed equipment, while other facilities have limited automation and can change day to day. This type of dynamic environment could be challenging for certain AMR vendors. Both facility types would benefit from automated material handling, but the approach and deployment specifics would be different.

It’s also important to consider aisle widths. AMRs have footprints of different sizes and require their safety fields to fit within a given space.

If your aisles aren’t big enough to accommodate [its safety fields], you might have an AMR that can boast a top speed of 2 m/s [or] 3 m/s, but only ever go 0.5 m/s because the aisles are too narrow for it to actually get up to that top speed.

Tom O’Neill

Senior Product Manager, OTTO Motors

4. Throughput

This is where you need to determine how fast your materials must move to achieve ROI, indicating if a single AMR or multiple are needed. To determine throughput, you can ask yourself the following questions:

- How many parts are needed at the line to maintain production?

- How many parts can fit on a single cart? A single pallet?

- How long will it take for an AMR to get from A to B?

Then, you need to think about how long the AMR takes to complete required tasks. For example, how long does charging take? How long does it take to connect to a conveyor and release the materials it’s carrying? Is the aisle straight or are there twists and turns that will slow down the average speed of the vehicle?

5. Fleet Management

If you determine that you need more than one AMR, you’ll require a highly sophisticated fleet management software. This software will be your traffic coordinator and team leader. You should begin considering fleet management softwares on the basis of three main criteria:

a) Traffic management: A powerful software will route and schedule AMRs to ensure they are moving efficiently and completing tasks on time.

b) Scalability: As your material handling needs grow, the software needs to be scalable to accommodate an increasing number of AMRs without sacrificing productivity.

c) Integrations: A solution that can integrate into existing systems and technologies will enable a seamless transition into automation.

6. Ease of Use

Since it is the fleet manager or on-vehicle UI that your engineers and lineside personnel will actually use when interacting with the system, you need an easily adaptable solution. You should ask questions like:

- What does the deployment process look like?

- How easy is it to make changes?

- Do I have to program each individual vehicle or can I apply changes to all or multiple vehicles at once?

Contrarily, you may want to restrict access to select workers. That’s why it’s extremely important to select a secure solution that integrates with your IT infrastructure on the basis of access management, application and network security, external hosting security, information protection and encryption management.

7. Maintenance and Optimization

While AMRs maximize uptime, sometimes, blockages may occur in the facility, limiting productivity. You need to select a system that quickly notifies you of why, where and when the productivity reduction occurred so you can prevent it from happening again.

Additionally, solutions with a strong data and analytics tool can help you keep a tab on the health of your system and make smarter decisions that can lead to optimized performance.

Analytics help determine where those issues could occur and it can really help prove out your ROI.

Tom O’Neill

Senior Product Manager, OTTO Motors

Adoption of material handling automation technology is rapidly increasing as manufacturers look to improve productivity, safety and efficiency in their operations. Specifically, most manufacturers are looking into AMRs, with 75% of webinar attendees currently evaluating the technology. As you sort through potential AMR vendors, it’s important to consider your specific requirements and determine which vendor can best meet your needs. Watch the webinar, “Complete Guide to Choosing the Right AMR for Your Material Handling Needs,” for a deeper dive into these considerations.