Blog

AMA: Which material handling workflows are autonomous mobile robots best suited to automate?

In this blog series, manufacturing facilities and warehouses ask their top industry and product questions, and OTTO’s material flow experts answer them.

When manufacturers are looking to introduce autonomous material handling technology into their facility, the first step is to identify the workflow they want to automate. Based on this workflow, manufacturers can begin evaluating autonomous mobile robot (AMR) solutions in the market to determine which provider is best suited to meet their needs.

Which material handling workflows are autonomous mobile robots best suited to automate?

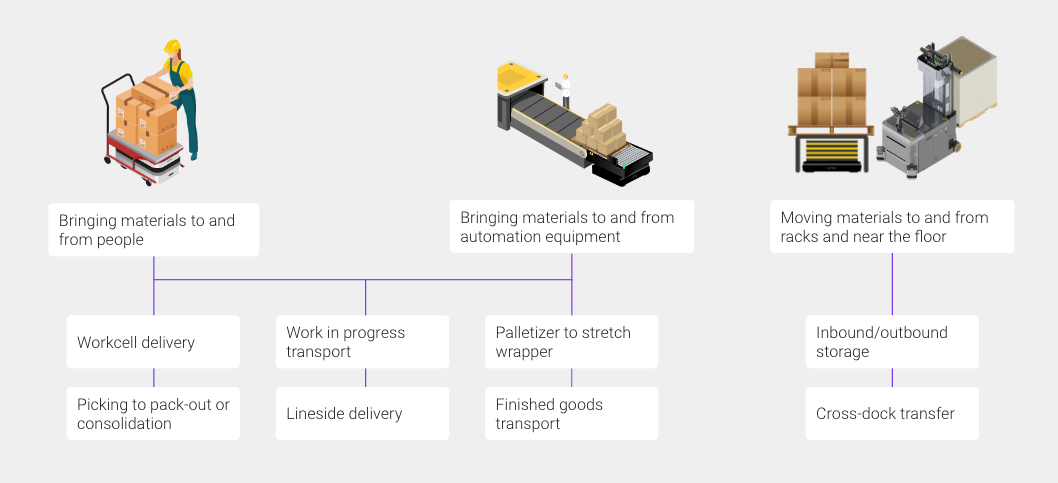

The material handling workflows that are best suited for AMRs include:

- Workcell delivery: When an operator's materials run low in their cell, they call OTTO for delivery. OTTO arrives with a cart of new materials, swaps it with the depleted one, and transports the empty cart away from the workstation.

- Picking to packout or consolidation: Once a worker’s picking tasks are complete, OTTO transfers the picked materials to packout or consolidation.

- Work-in-progress (WIP) transport: OTTO can deliver material to the assembly line at the designated location as well as autonomously move it from station-to-station along WIP.

- Lineside delivery: OTTO reliably delivers both kitted and bulk products to the lineside for replenishment, ensuring timely and accurate supply to sustain uninterrupted production.

- Palletizer to stretch wrapper: Once the palletizer has finished loading boxes on a pallet, OTTO can be triggered automatically with facility integration to come pick up the palletized goods and drop them off at the stretch wrapper.

- Finished goods transport: Transferring finished goods from the end of the production line for storage or shipment is the last crucial step in getting products to customers. OTTO picks up the finished goods and transports them to a designated location for storage or staging.

- Inbound/outbound storage: OTTO eliminates non-value-added manual transport from inbound/outbound docks to storage or staging. OTTO efficiently clears or creates staging lanes, delivering materials to their next destination, including storage, lineside, and shipping.

- Cross-dock transfer: Improve efficiency and safety by utilizing OTTO for long horizontal material transport between the inbound and outbound docks.

Automating each of these workflows helps manufacturers improve safety and boost productivity by keeping skilled workers focused on the tasks they were hired for, rather than taking time away from value-added tasks for repetitive material movement.

To help determine the type of AMR best suited for each workflow, they are grouped into three buckets:

- Bringing materials to and from people

- Bringing materials to and from automation equipment

- Moving materials to and from racks and near the floor

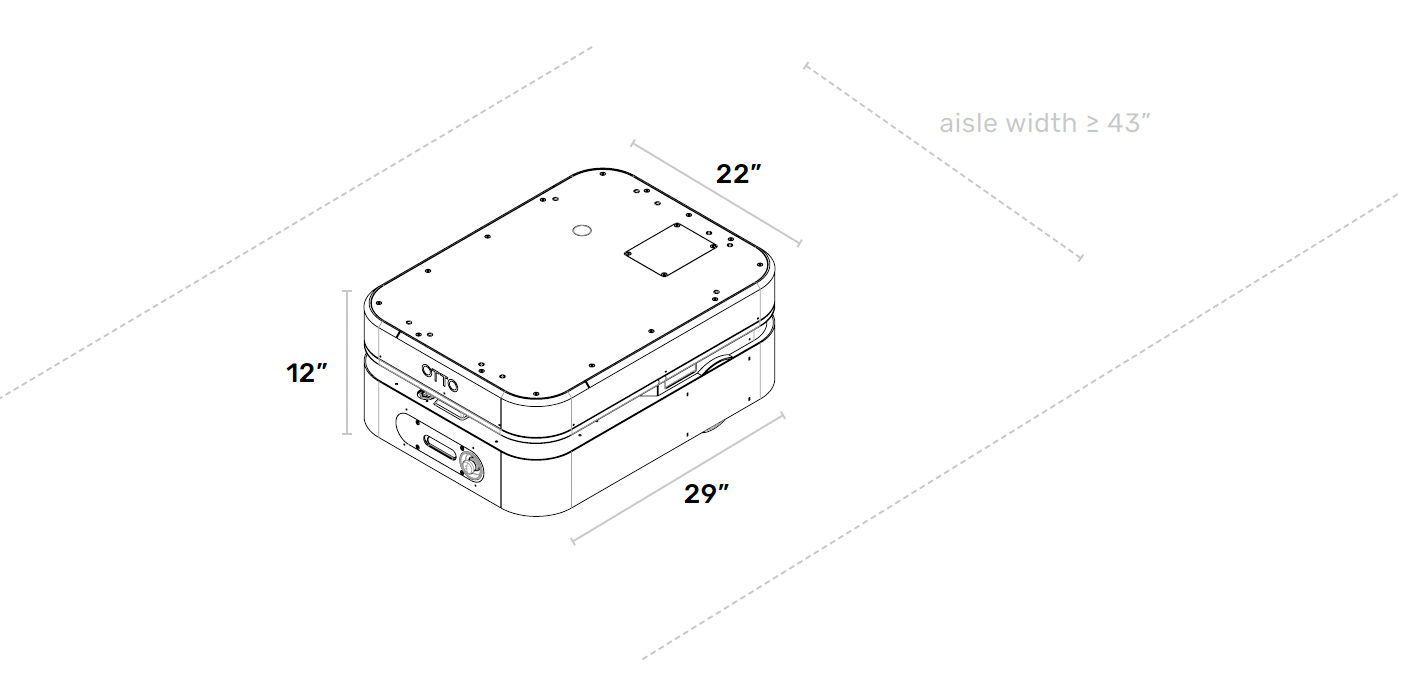

Different AMRs are best suited for each of these unique workflows. AMRs with smaller payload capacities, such as OTTO 100 with a 150 kg capacity, are ideal for person-to-person use cases. Equipped with carts, OTTO 100 moves boxes, bins, carts and other lightweight payloads that a person would typically carry or push themselves.

When a forklift or tow-motor would need to be involved to lift the required payload, a larger AMR is necessary, such as OTTO 600 with a 600 kg capacity, OTTO 1200 with a 1,200 kg capacity, or OTTO 1500 with a 1,900 kg capacity. Many of the workflows above involve lifting a pallet off a stand or conveying a pallet onto an AMR from another piece of automation equipment, which is ideally suited for OTTO 1500. OTTO Lifter, our autonomous forklift with a payload capacity of 1,200 kg, is also ideal for working with existing islands of automation, and it is our only AMR that can pick up and drop off materials from the floor.

Once a manufacturer knows which material handling workflows they would like to automate with AMRs, the next step is to evaluate which provider is best suited to automate those workflows. To help guide you through this stage, reference this whitepaper on the 8 key considerations when assessing AMR vendors.

Written by Poonam, Product Marketing Manager at OTTO by Rockwell Automation.

If you’d like to submit a question for our material flow experts to answer, please fill out the form below.

Ask a question

Subscribe to our newsletter

Stay in the loop on product news, case studies, upcoming events and more.