Blog

State of the packaging industry: 3 key insights from PACK EXPO 2025

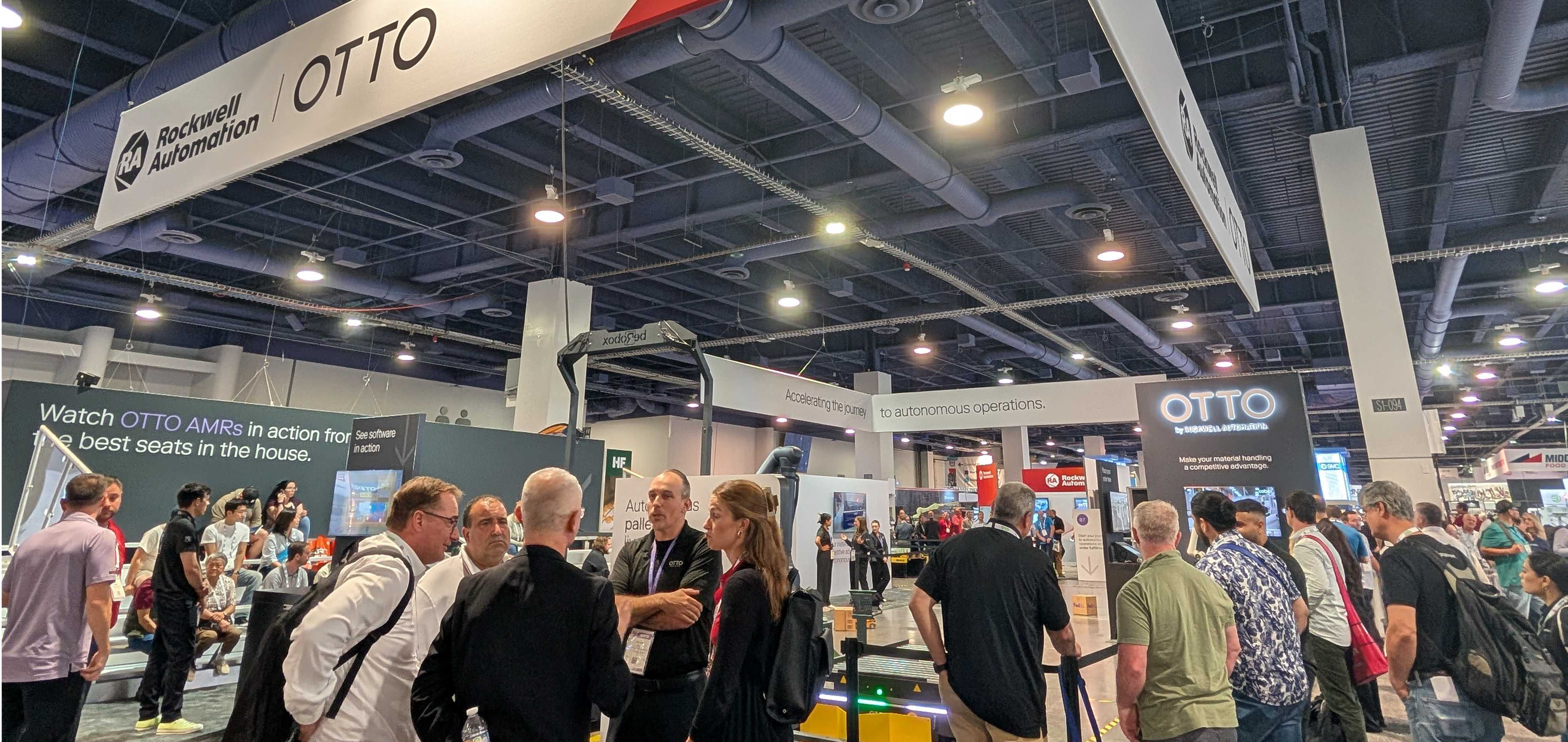

Celebrating its 30th anniversary, PACK EXPO 2025 Las Vegas brought together over 35,000 attendees and 2,300 exhibitors from around the world to see what’s new in packaging and processing. Across the show floor, the spotlight was on automation—from proven material handling solutions to the latest advances in smart conveyance, palletizing, labelling, filling, inspection and more.

The OTTO team spent three days exhibiting, exploring the show floor, and connecting with attendees from over 40 vertical industries including food and beverage, life sciences, cosmetics, and consumer packaged goods. We heard firsthand about the challenges manufacturers are looking to solve and gained a clear view of where their operations stand today. Here’s what we learned:

- Flexibility is crucial to keeping pace with shifting consumer demand

- Sustainability is a powerful influence on innovations in packaging automation

- Autonomous operations are moving from concept toward reality

1. Flexibility is crucial to keeping pace with shifting consumer demand

CPG manufacturers come to PACK EXPO searching for new ways to increase efficiency, improve plant safety, and reclaim valuable floor space. To achieve these goals in an industry where consumer demands are constantly shifting, flexibility is a requirement for any automation solution manufacturers consider.

With rapidly shifting consumer demand, seasonal SKUs, and frequent line changeovers, production lines must adapt quickly without costly downtime or extensive retooling. The challenge of meeting customer demands—including customization—has consistently ranked among the top five challenges for manufacturers, with 43% of respondents in the 2025 MHI Industry Report rating it as extremely or very challenging.

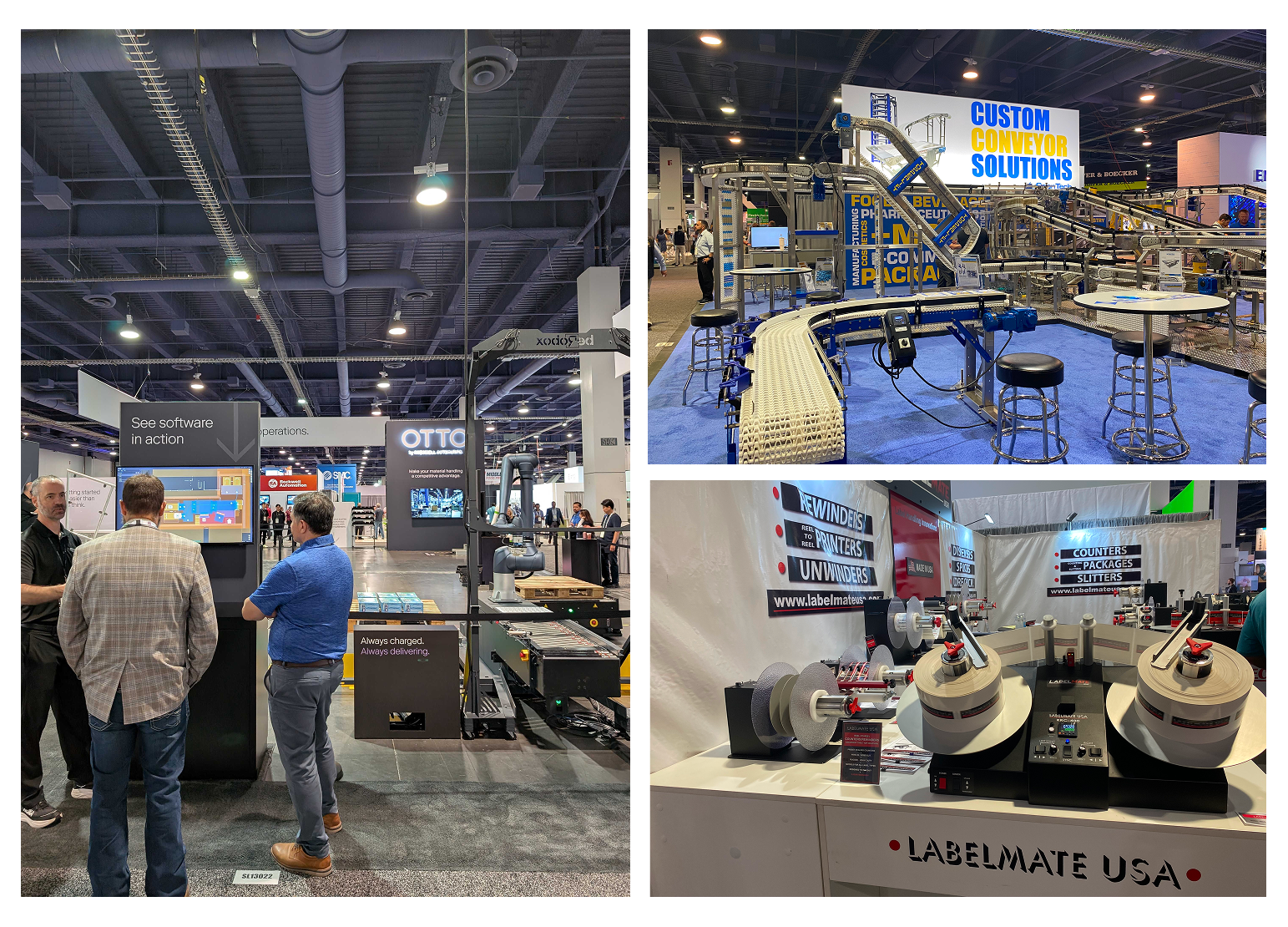

On the show floor, this need was reflected in solutions like autonomous mobile robots (AMRs) that can be easily redeployed across lines without fixed infrastructure, enabling manufacturers to quickly repurpose floor space and adjust material movement workflows as operational needs change. Other exhibitors showcased modular conveyors that adjust on demand, custom label printing technologies that support rapid SKU changeovers, and more.

Exhibitors on the show floor displayed solutions to improve plant flexibility, including AMRs moving material to the palletizer at the OTTO by Rockwell Automation booth, custom conveyor solutions at the Span Tech booth, and custom label solutions at the Labelmate USA booth.

2. Sustainability is a powerful influence on innovations in packaging automation

Companies are facing growing pressure from both regulatory actions and rising consumer expectations to reduce packaging waste, eliminate dyes, cut carbon emissions, and improve recyclability. The FDA, for instance, has announced measures to phase out petroleum-based dyes by the end of 2026. At the same time, with the supply chain industry responsible for 90% of global emissions, the United Nations is calling for a 45% reduction by 2030 to reach net zero by 2050. Consumers are also increasingly seeking sustainable products, often favoring brands that prioritize eco-conscious practices.

This focus on sustainability is also a top priority for manufacturers. According to the 9th Annual State of Smart Manufacturing Report, 98% of manufacturers now have a sustainability or ESG policy in place, with nearly half of those being formalized company-wide. To support these initiatives, many are also restructuring facilities and investing in new technologies. At PACK EXPO 2025, the commitment to sustainability was unmistakable: one of the six pavilions was dedicated to “Reusable Packaging,” and two of the five main speaking stages focused entirely on green manufacturing. On the show floor, this priority came to life in innovations like recycled-content films, mono-material packaging, compostable laminates, and new recyclability technologies.

3. Autonomous operations are moving from concept toward reality

With persistent labor shortages and rising consumer demand, connected systems are moving from “nice to have” to business critical. Today, manufacturers are prioritizing investments that progress them towards end-to-end automation and orchestration technologies, enabling machines, software, and robotics to operate seamlessly together across the production cycle.

At PACK EXPO 2025, Rockwell Automation and OTTO demonstrated what that vision looks like in practice. A connected workflow linked upstream operations in Rockwell’s booth with OTTO demonstrating downstream palletizing, staging, and fulfillment. Attendees followed a can of soda from raw materials to outbound logistics, watching as OTTO 600 and OTTO 1500 demonstrated palletizing and staging. Plus, OTTO 100 with a FANUC cobot performed on-demand order fulfillment. Integrated with Rockwell’s middleware, the system showed how autonomous material movement can align with production demand in real time, improving safety, freeing floor space, and increasing efficiency across the packaging line.

PACK EXPO 2025 Las Vegas reinforced that the packaging and manufacturing landscape is evolving rapidly. Companies that embrace innovation and invest in versatile, integrated solutions will be best positioned to thrive in this competitive, fast-changing industry.

Learn more about how OTTO works for the food and beverage and consumer packaged goods industries.

Subscribe to our newsletter

Stay in the loop on product news, case studies, upcoming events and more.