Blog

'Tis the season of high demand and few available workers to meet it

With the holiday season upon us, factories and warehouses are feeling the impact of rising order volumes and declining labor availability. From clothing to electronics to automobiles, every industry is experiencing high demand—but many are unsure how to meet these needs efficiently.

Holiday demand is rising—again

Holiday shopping typically begins in October, but the heaviest impact hits manufacturers and retailers in November and December. This year, holiday sales are expected to surpass last year’s levels, with Deloitte projecting overall retail growth of 2.9–3.4% and e-commerce sales climbing 7–9%—a significant increase when holiday spending accounts for 19% of annual sales for the retail industry.

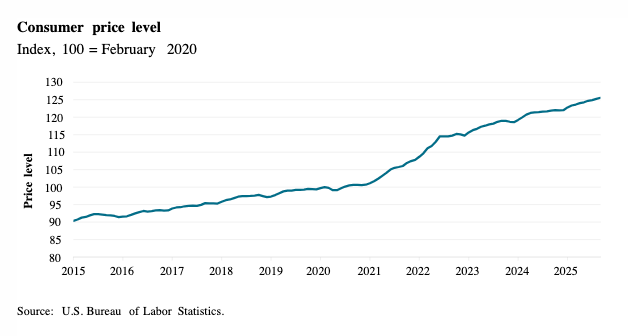

At the same time, prices have risen roughly 25% over the past five years, making consumers increasingly price-conscious. To stay competitive, manufacturers must find ways to manage costs while keeping products affordable.

Image 1: Prices have risen 25% since 2020, creating weaker consumer confidence.

To keep pace with these pressures, many factories and warehouses rely on temporary workers to manage the seasonal surge.

Seasonal workers are in high demand and low supply

Due to the greater demand for products around the holiday season, companies often find themselves with additional positions available, but no one to fill them. According to Indeed, holiday hiring is up 12% in 2025, with Amazon alone expected to hire 250,000 additional seasonal employees in the U.S. this year.

However, finding these workers is becoming increasingly challenging. In fact, nearly 75% of manufacturing managers identified skilled labor shortage as their biggest challenge, and by 2033, over 1.9 million manufacturing jobs are projected to be unfilled. This widening gap is leading companies to explore alternative solutions to meet both annual and long-term demand.

Robotics and automation: The gift that keeps on giving

Many major retailers and logistics companies—such as Amazon, Walmart, UPS, and FedEx—already rely on automation and robotics to handle increased order volumes during the holiday season. These robots support tasks like sorting, picking, and moving materials across warehouses and manufacturing facilities.

With e-commerce sales continuing to break records, speed and accuracy are more important than ever. Automating material handling tasks frees workers to focus on higher-value tasks, increasing throughput, flexibility, and speed—enabling companies to accept later order cut-offs and capture more sales.

While automation provides immediate benefits during peak season, it also helps companies adapt to changing year-round shopping patterns. With the rise of events like "Amazon Prime Days" and "Black Friday in July,” global shopping trends have shifted, and now, more than 40% of shoppers begin their holiday shopping before November. It’s more important than ever before for manufacturers to be prepared for these year-long fluctuations in demand.

As we feel the pressure of this season’s surge, now is the time to set up for success next year by evaluating AMR solutions. If you’re interested in getting started, register for our webinar, “Unlock AMR value: Building a results-driven business case.”