Blog

Building a scalable AMR solution: keep traffic flowing

This is the second blog post in our series on scalability where our VP Product, Jay Judkowitz, shares valuable guidance on achieving scale with autonomous mobile robots (AMRs).

You’ve learned how OTTO scales, but how do you keep traffic flowing at high scale?

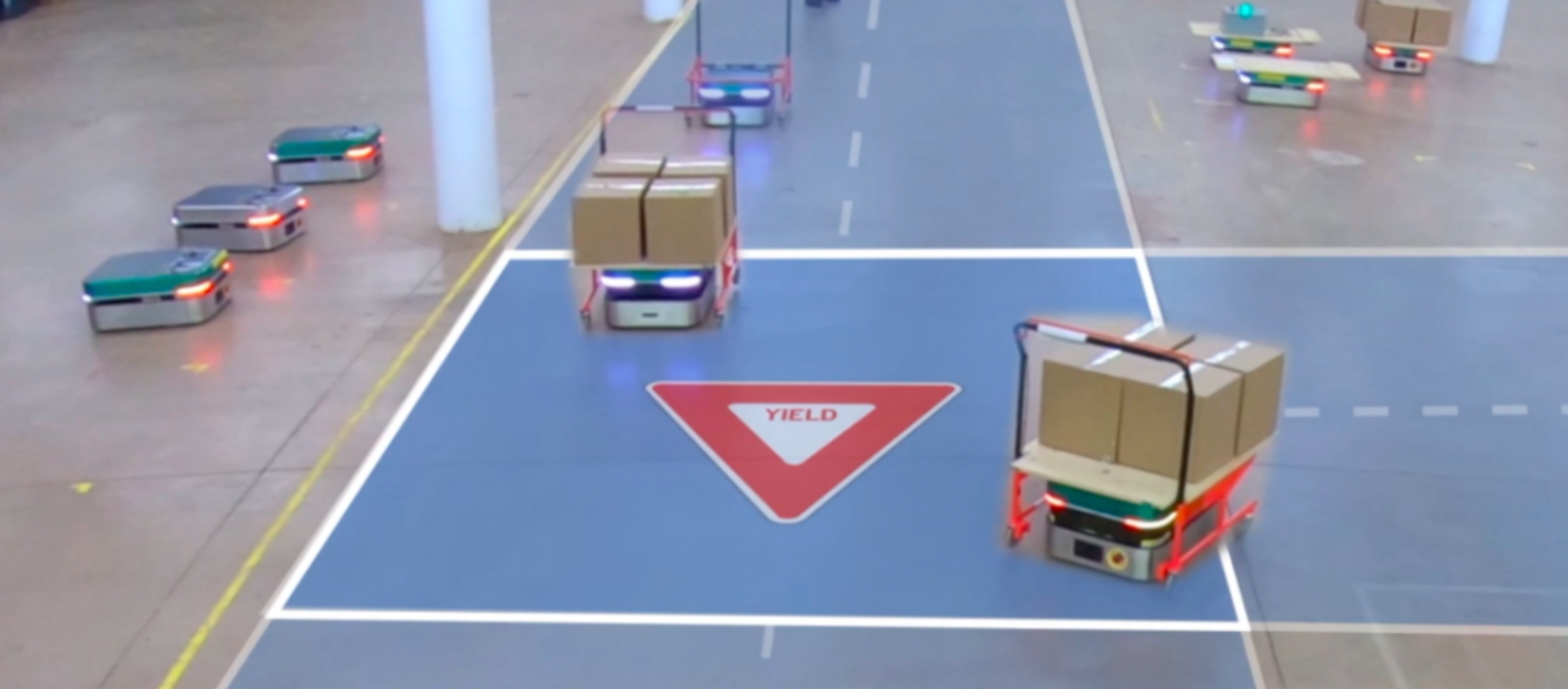

Think about the traffic on your morning commute. Planning roads, signs, and traffic lights is easy if you are the only one on the road, but with thousands of drivers in the same place, civil engineers need to plan for scale with care. One missed detail means gridlock and interminable backups. Planning for 100 AMRs is the same.

Here are 6 ways OTTO keeps your material handling flowing at scale:

1. Don't congregate at congestion points

When a location required by a vehicle (such as a work location, charger, or parking place) is taken, OTTOs will choose an equivalent place to go if one is available. If the occupied endpoint is the only one available, the incoming vehicle will back off to make sure that the current occupant can get out to make way for the next occupant.

2. Give each other space

All AMR solutions make sure vehicles don’t collide with each other. OTTO’s go further and understand each other’s safety buffers and avoid them so that they don’t slow each other down or trigger unnecessary safety stops.

3. Track offline vehicles

It is an important safety step to give a wide berth to live vehicles that dropped off the network and whose location is not precisely known. But, if a vehicle has been taken off the network deliberately and is known not to be able to take jobs and drive, live vehicles can safely drive through the offline vehicle’s space and keep traffic flowing.

4. Fine-grained traffic control

Speed limits, stop signs, one-way zones, queueing points, and other specific driving instructions can be added to OTTO maps so that vehicles can move as fast and safely as possible, taking into account the appropriate behavior in different parts of your facility.

5. Configurable patience

In facilities where people are more likely to stand still and engage with equipment or each other, OTTOs can be configured to more quickly and replan paths when blocked and not wait for people to move. In facilities where people tend to pass through the vehicles’ paths relatively quickly, OTTOs can be configured to slow down and wait for people to move without triggering replanning.

6. Programmable interlocks

Besides human-controlled workstations to summon or dispatch vehicles, Fleet Manager has APIs to allow factory control systems to pause and resume vehicles so that there is no wait for a human to take action to keep jobs moving along.

Next week, in the final part of the series, I will evaluate questions you should consider as you embark on a scaled AMR deployment.

Learn more about traffic control with OTTO Fleet Manager.