Blog

Being on time, every time: On-time delivery & customer satisfaction

Meeting customer’s expectations and delivery requirements must be a top priority for any business to succeed. However, meeting those expectations is easier said than done. In fact, customer demands for faster response times (51%) was the third highest company challenge outlined in the 2022 MHI Annual Industry Report.

This challenge has been consistent year over year, ranking fourth in the 2021 report (47%) and third in the 2020 report (48%). Previous years have also listed customer demands on costs, rising customer service expectations, and customer demands for customization as top six company challenges as well, highlighting the importance of the customers’ impact on your operations. The good news is those expectations are usually straightforward: orders should be shipped accurately and arrive on-time.

Meeting these expectations proves difficult when companies struggle to meet other key deadlines upstream in their supply chain. Poor On-Time Delivery (OTD) performance impacts more than customers — it’s usually an indicator of poor production efficiency and material handling procedures.

Consistent difficulty with on-time delivery can cause issues that affect many other areas of a company’s supply chain. A few examples include production delays due to material shortages, avoidable expedited shipping costs, and being overwhelmed with customer complaints. Sometimes, it even results in lost customers. In a survey, 17% of customers said they would stop buying from a company after one late delivery, and more than half said they’d abandon the company after two or three.

There is also the bigger issue that regularly delivering late becomes a difficult habit to break. Following a ‘routine’ of accepting poor on-time delivery performance affects every area of a business and can irreparably damage customer relationships.

Image 1: The top 6 supply chain challenges as ranked by MHI’s 2022 Annual Industry Report.

Measuring on-time delivery (OTD)

Different organizations measure on-time delivery in different ways. In basic terms, OTD is a calculation of the amount of shipments delivered on time to the customer in relation to the total number of orders shipped. If the number is below your company’s benchmark, it likely means there are deeper issues that need to be addressed. Poor OTD is likely just a symptom, not the core problem in the supply chain.

Clearly defining your benchmark OTD is the first step in figuring out how to improve it. Typically, to outperform competitors, your OTD benchmark should be 95% or above, but this will differ by company and industry.

Improving on-time delivery

OTD for shipments within a production supply chain is a difficult metric to track, but improvement in this area has obvious value. The on-time arrival of materials needed for production is integral to the efficiency of the production line. It’s this point in the manufacturing process where the importance of good logistics and good inventory management practices intersect.

To improve OTD, some companies have tried streamlining order picking, minimizing packaging, and implementing inventory management systems. Employee incentives are also proven to boost performance by as much as 44%. Many manufacturing facilities are also implementing material handling automation technology through autonomous mobile robots (AMRs) to increase the efficiency and productivity of their supply chain.

Automation technology helps solve low OTD

Leveling production and automating material handling through lean processes are two proven ways to optimize the availability of materials for production and improve your OTD percentage. This helps solve the “customer demands for faster response times” company challenge from the 2022 MHI Annual Industry Report. With both approaches, each step in the production supply chain is accounted for, helping to meet internal production deadlines and keeping lines moving.

Chart 1: Increasing efficiency of materials handling not only improves OTD, but it also reduces the overall production cost of goods.

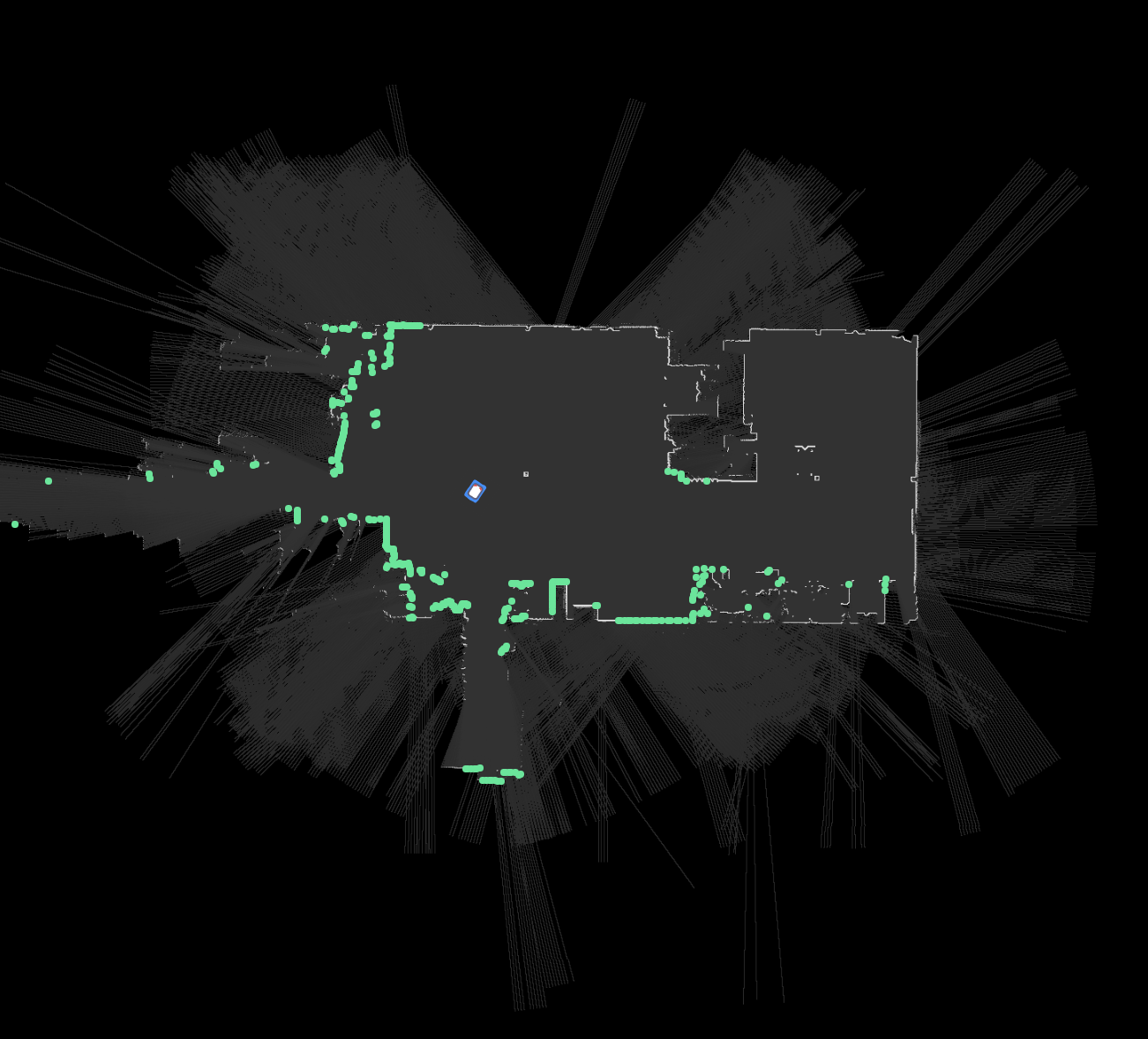

For example, materials management of parts and inventory can be tracked by user, task, and location through a centralized system, OTTO Fleet Manager, which provides better inventory visibility. Upgrading to automated material handling systems means using technologies such as robotics, sorters, conveyors, and RFID (barcode) scanners.

In addition to increasing efficiency in supply chains to improve OTD, AMRs also help improve the flexibility of supply chains, enabling companies to meet rising “customer demands for customized products”. Automation is also a cheaper alternative for manual material handling, enabling a reduction in costs for companies and thus meeting the expectation of “customer demands on costs.” Automating material handling processes helps companies meet their on-time delivery benchmarks, which improves the customer experience.