Blog

The future of AMRs and AGVs in material handling

Last month, David Northup, our Director of Product Management, hosted “The Best of Both Worlds: Unlocking the Productivity of AGVs and AMRs”, a webinar that analyzed the differences between AMRs and AGVs, from their technology to their applications. He also introduced the idea of Graph-based Planning, an algorithm that enables manufacturing facilities to achieve the benefits of both AMRs and AGVs in one robot, including the predictability of AGVs alongside the flexibility of AMRs.

At the end of the webinar, David began discussing the future of AMRs and AGVs together. Increasingly, the two technologies are being used in the same facilities for different applications and workflows, as their unique benefits complement each other well. AMRs and AGVs need to work together, and interoperability is key to this advancement.

Interoperability is really a term that we mean to allow dissimilar robots to occupy the same space intelligently. So this means communicating with one another to share information about where they are [and] what their intentions are to allow them to be good citizens and share the space collaboratively.

David Northup

Director of Product Management, OTTO Motors

OTTO Motors and InOrbit demonstrated interoperability between an AGV and an AMR at the AMR Conference in October 2022 by showing how the two robots can work together. This was facilitated by a new open source Ros2 VDA 5050 connector developed in part by the two companies.

Alongside interoperability, here are five expectations for the future of AMRs and AGVs working together.

1. AMRs and AGVs will only be differentiated through path planning options

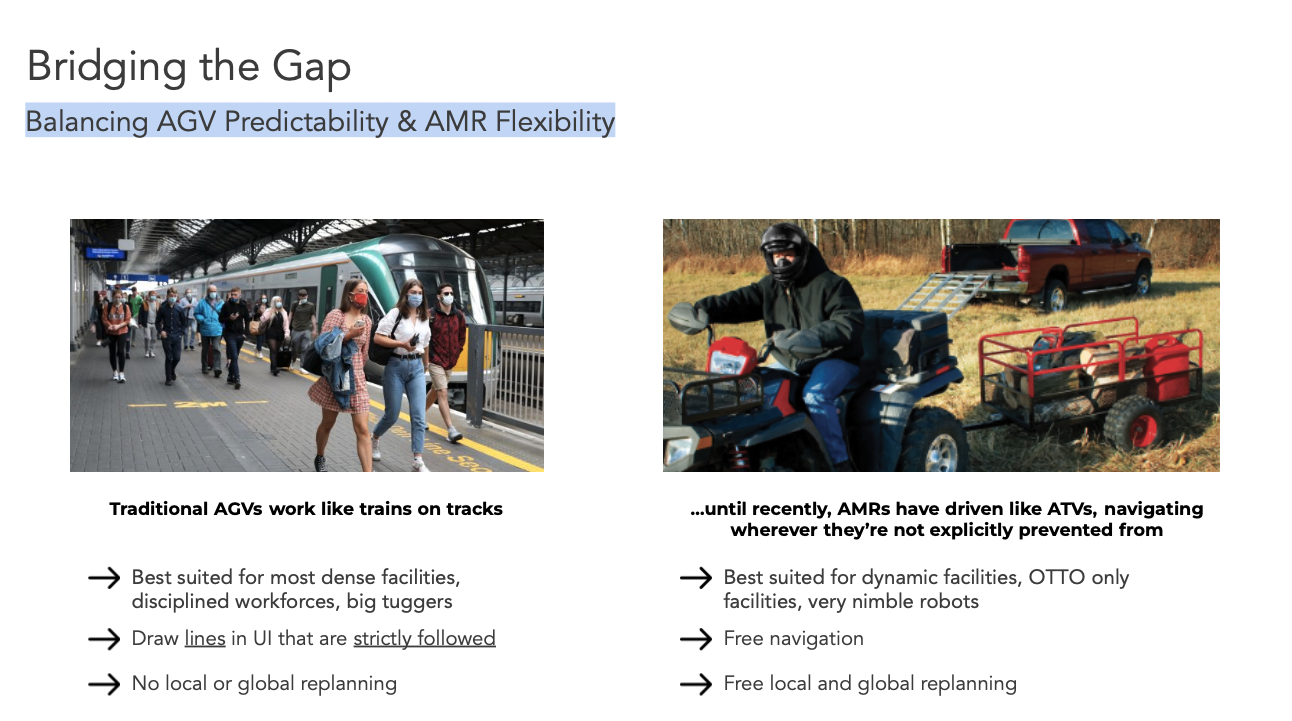

As material handling robots like AMRs and AGVs become increasingly similar, their main differences will be between path planning options. Some AMRs will retain Search-Based Path Planning, which is similar to an ATV in a field. The ATV has no prescribed path and can take whichever route is most efficient to its destination. Moreover, some AGVs will continue to act like a train on a track, following a specific path and unable to deviate from it when an obstacle blocks the route.

On the other hand, some material handling robots will use Graph-Based Path Planning, which acts like a car on a road. The car will use prescribed paths to get to the destination, but can deviate from the path when something blocks the route. This results in some AMRs becoming increasingly predictable as some AGVs become increasingly flexible.

2. Similar communication standards will govern both AMRs and AGVs

Recent efforts in the material handling industry have produced attempts at standardizing communication protocols between robots from dissimilar vendors and dissimilar types, such an AGV versus AMR. Primarily, this is motivated by no single vendor having a large enough fleet of robots and capabilities that can address the diverse and growing set of needs that a typical large-scale manufacturing facility or warehouse may have.

Thus, through communication standardization, the industry hopes to facilitate the interaction of these unique robots to improve efficiency and safety through centralized coordination. OTTO Motors is taking an open approach to this challenge by investing in and contributing to open-source efforts that benefit the industry as a whole. The robots that do not comply with these emerging standards will be at a disadvantage in the industry.

3. Standards will shape and be shaped by the market

Typically, the AGVs and AMRs that a particular vendor provides will only work with their own specific fleet management software. However, this meant customers using dissimilar robot types had been required to adapt or create their own means of communication between different robots. Otherwise, the different robots would have been difficult to deploy, had interoperability issues, and sometimes needed to use completely separate paths, causing a loss in facility space.

Thus, the early efforts for communication standardization have been driven by market demand from customers who require a fleet management system that is capable of operating a large and diverse fleet of robots.

Once you have that capacity for everyone to speak the same language, now you can do interesting things on top of it. I think this is the industry coming together and users demanding it, and AMR vendors satisfying that demand.

Florian Pestoni

CEO, InOrbit

VDA 5050, a standardized interface for AGV and AMR communication, was actually born out of the automotive manufacturing industry, one of the largest users of material handling robots worldwide. Increasingly, however, this market need is encompassing all industries as robotics vendors worldwide learn to work together.

4. There is a proliferation of third party fleet management solutions

Today, AMRs and AGVs are still primarily designed for use in fleets of robots from the same vendor and of the same type. This will continue to be the primary use case and most efficient deployment style for the foreseeable future, since each vendor is best equipped to manage fleets of their own robots.

With the advent of interoperability standards, there has been an emergence of third party fleet management solutions that aim to direct communication, coordination and control of fleets that include heterogeneous robot types and vendors. These systems are currently only capable of basic communication and control, but over time, they will evolve to become more advanced and powerful.

[Interoperability enables] different robots from different vendors working together to complete a more advanced mission.

Florian Pestoni

CEO, InOrbit

5. Location tracking systems will improve for better coordination and safety

Location tracking systems provide manufacturing facilities a mechanism for establishing a global tracking reference for any object that a facility manager needs to locate.

In an ideal world, an AMR or AGV would have full awareness of all other moving objects within their operating domain, including humans and other manually operated machines such as a forklift. With this global knowledge, they would be able to respond both reactively and proactively to the objects they are encountering. Currently, however, robots are only able to reactively respond when they encounter an obstacle.

As location tracking systems improve, robot fleet managers will know the location of a manually-operated forklift or human, for example, that may be blocking an aisle way on the future path of a robot. Then, the fleet manager could use this awareness to alert the AMR in advance, allowing the robot to proactively plan an alternative route to its destination that is more efficient, coordinated, and safe.

The robotics industry is an innovative industry. It is constantly evolving to meet increasing consumer needs and market trends. While AGVs and AMRs will continue to have distinct technology and applications in the interim, the future looks promising for material handling robots and their collaboration in manufacturing facilities worldwide.