Blog

How a tier 1 automotive supplier navigated the 5 stages of AMR selection

Selecting an autonomous mobile robot (AMR) solution is a strategic process that goes beyond the robot itself. It requires alignment across technical needs, operational goals, and stakeholder priorities. In The manufacturer’s playbook for AMR selection, this process is broken down into five clear stages to help manufacturers evaluate, validate, and move forward with confidence. Learn more about the five stages in this blog.

One of the world’s largest Tier 1 automotive suppliers—designing and producing interior components for one in three vehicles globally—used this framework to select and deploy an AMR solution. The result: 11-month ROI, 15% reduction in work cell size, and zero safety or near-miss incidents.

Here’s how their Controls Engineer navigated each stage of the AMR selection process:

Stage 1: Define the problem and explore potential solutions

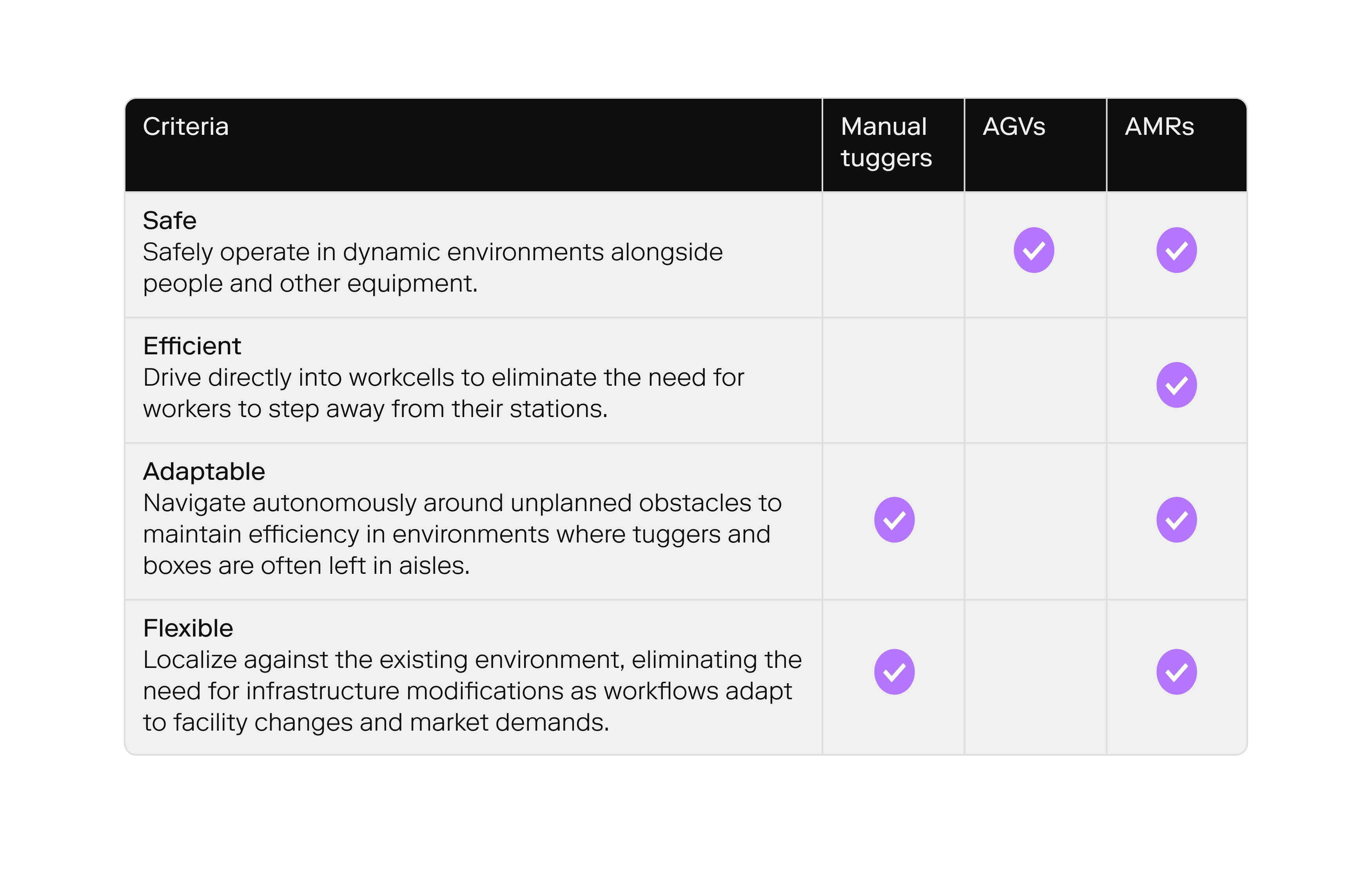

To stay competitive, the Fortune 500 manufacturer needed to reduce costs, improve safety, and increase plant efficiency—without compromising flexibility or floor space. The Controls Engineer evaluated three potential solutions for material movement between the warehouse and workcells in their technology bay: AMRs, automated guided vehicles (AGVs), and manual tuggers.

Image 1: The manufacturer’s criteria when evaluating three solutions for material movement.

Stage 2: Independently research vendors to pre-qualify solutions

With AMRs identified as the right fit for their operational needs, the Controls Engineer conducted independent vendor research to determine the vendors best equipped to meet the facility’s requirements. This included:

- Online research to compare key differentiators

- Conversations with other manufacturers to develop a shortlist based on critical success factors

Stage 3: Meet with your chosen vendor to validate the solution

Early in this stage, the Controls Engineer engaged in 1:1 conversations with shortlisted vendors to assess how well each solution aligned with the plant’s technical and operational needs. Ultimately, OTTO was the vendor that met their criteria for performance, scalability, and support.

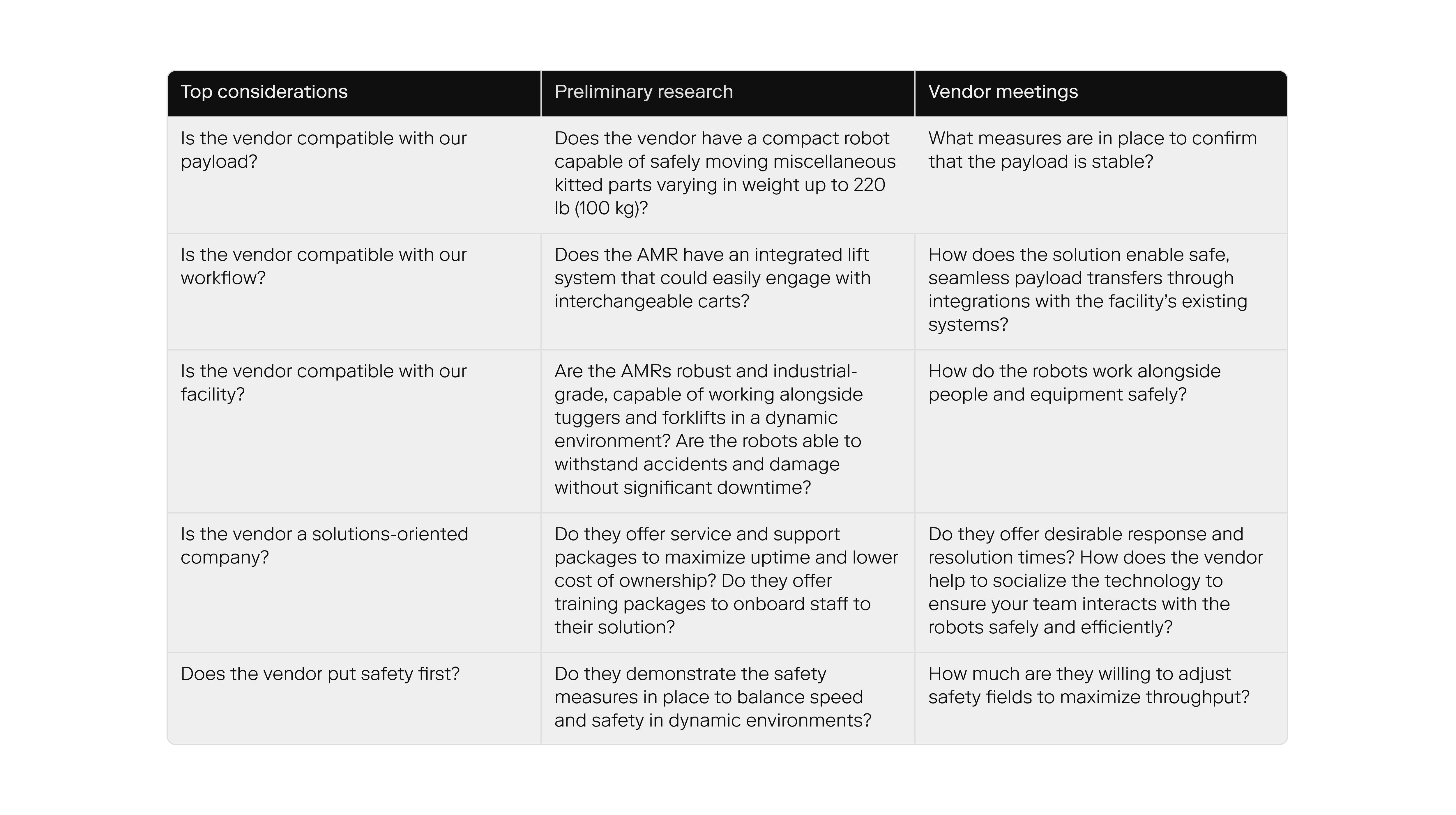

While the Controls Engineer conducted their own independent validation, based on the facility’s requirements, it’s likely that key considerations during this stage included these top considerations and questions:

Image 2: Potential considerations used during vendor evaluation.

Stage 4: Build a tailored business case to gain stakeholder buy-in

The team worked with OTTO to finalize ROI calculations and build a business case aligned with stakeholder priorities. To validate that the solution would meet these goals, they conducted on-site testing to confirm the following:

- How the AMRs performed during demand peaks and valleys

- How traffic could be controlled and where endpoints would be located

- How the moving racks with hanging product impacted AMR localization

- Whether the facility had the IT infrastructure to support the deployment

The final checkpoint was securing stakeholder buy-in by addressing their top priorities:

- The safety team: Demonstrated the safety features of OTTO AMRs to prove that replacing manual tuggers would operate safely alongside workers.

- The IT team: Outlined IT infrastructure requirements and associated costs.

- The Engineering Director and the plant’s General Manager: Presented ROI calculations based on projected number of AMRs and all associated costs—software, deployment, chargers, training, and service and support.

Stage 5: Submit the business case

With stakeholder alignment in place, the Controls Engineer submitted the full proposal to the purchasing team. Once approved, the project moved into solution design and deployment planning.

Ultimately, seven OTTO 100 AMRs were initially deployed to support the 24/6.5 operation. Based on strong performance, the fleet was doubled over the next two years. To dive deeper into each stage, download The manufacturer's playbook for AMR selection.

Subscribe to our newsletter

Stay in the loop on product news, case studies, upcoming events and more.