Blog

Choosing the right AMR vendor: A guide to meeting your productivity goals

Engineers and Plant Managers play a critical role in turning company goals into measurable results by driving manufacturing process improvements facility-wide. Often, your company will issue organization-wide goals, such as increasing profits by 5% in the next five years, and your department will determine actionable, operational objectives to help meet those goals. For example, improving operational efficiency by increasing uptime, or increasing overall labor efficiency by eliminating non-value added tasks.

If you’ve determined that autonomous mobile robots (AMRs) could potentially help you meet these operational objectives, the next step is understanding how to qualify vendors to build your results-driven business case. In this blog, we’ll share how you can qualify vendors if your operational goal is related to increasing productivity.

Defining the underlying challenge

Productivity is a key driver for many manufacturers as it directly impacts operational success and profitability. When you begin researching and speaking with AMR vendors, ensure you have a good understanding of the underlying challenge driving needed productivity improvements.

There are three common challenges that lead to lowered productivity in dynamic manufacturing facilities:

- Ever-changing market demands make it difficult to maintain efficiency: Seasonal spikes in orders overwhelm the manual processes along the production line. A flexible solution is needed to adapt quickly to demand fluctuations and meet customer supply needs.

- Labor shortages are causing challenges sustaining productivity: Automating a repetitive task like material handling can help ensure your limited workforce is focused on high value-added tasks. This eases pressure on labor markets, and helps drive retention by reducing repetitive strain and creating a more rewarding work environment for the workers you do have.

- You need more flexibility to meet rising customer expectations: As the demand for customization grows higher than ever, we need a flexible solution to keep pace. This ensures we can quickly reallocate resources, adjust or redeploy AMRs to new workflows, and scale operations to meet new demands.

Image 1: According to the 2024 MHI Industry Report, the industry’s top challenges include hiring and retaining qualified workers and customer demands.

How to qualify vendors through independent research and 1:1 meetings

The key to success is finding a vendor which can help you achieve your unique operational goals. This means looking beyond surface-level capabilities to assess how their technology and expertise will directly support your operational goals—through both independent research and in-depth one-on-one conversations.

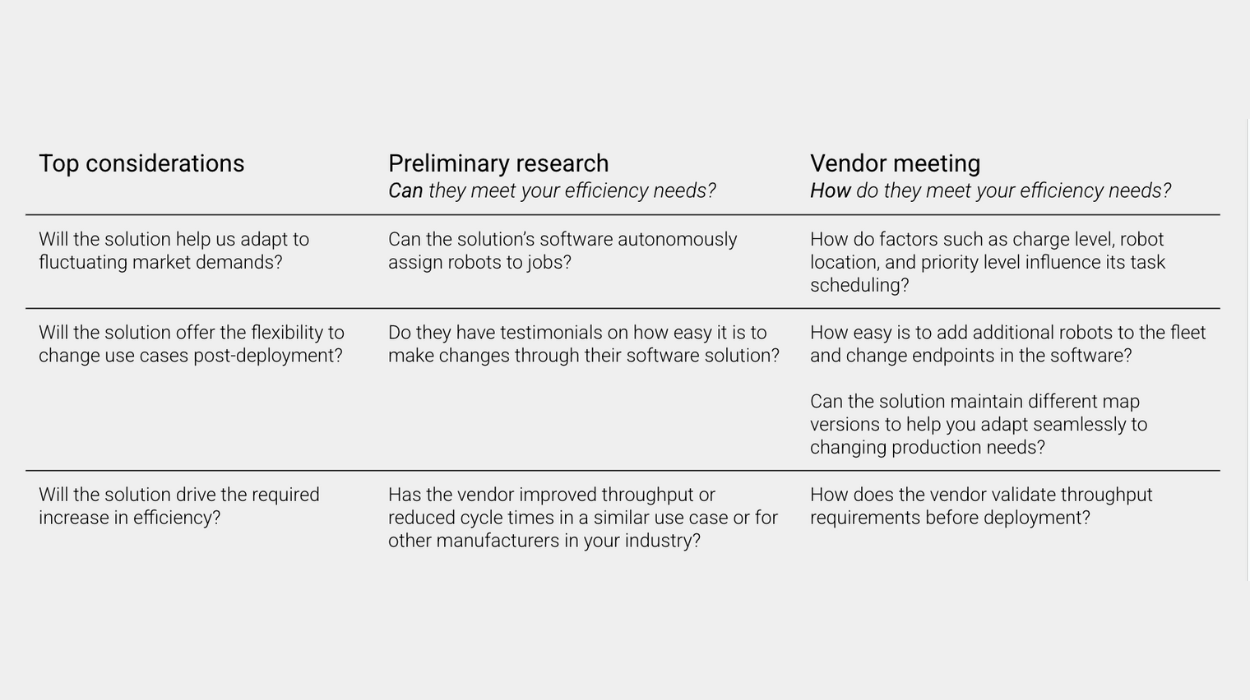

There are three main considerations when evaluating efficiency. Below, there’s a sample question you should be able to answer for each consideration following both independent research and your one-on-one meetings.

- Will the solution help you adapt to fluctuating market demands? This consideration confirms if their solution can handle the pace of change in response to today’s dynamic markets. You’re looking for vendors that offer solutions on how to handle market surges or flexibility within their software to change jobs based on priorities.

- Will the solution offer the flexibility to change use cases post-deployment? Being adaptable isn’t important only during initial deployment—it’s critical throughout the entire project. Look for testimonials from the vendors’ customers about how easily they’ve adapted their solutions over time. In meetings, dive deep into how software handles changes in the facility.

- Will the solution drive the required increase in efficiency? Ask the vendors about any simulation services they offer to confirm fleet size and expected throughput.

Image 2: Sample questions you should be able to answer following preliminary research and 1:1 vendor meetings for each of the top considerations above.

Increasing productivity may not be your only—or even your primary—goal. Learn how to build evaluation criteria that achieves your other operational goals by watching the full webinar, “Unlock AMR value: Building a results-driven business case.”

Subscribe to our newsletter

Stay in the loop on product news, case studies, upcoming events and more.